Casting Treatment

Home > Foundry > Entries > Casting Treatment

Steps to create Casting Treatment

Step 1: Go to casting treatment list and click on "Add Casting Treatment"

Series: Series will be auto selected as per doctype

Company: Select the company name from dropdown

Treatment Date: Date will be auto filled from current date in date format "DD/MM/YYYY"

Treatment Time: Time will be auto filled from current time

Sift: Enter shift timing of casting treatment

Supervisor Id: Enter the supervisor id of who will be supervising the casting treatment

Supervisor Name: Name will be auto fetched from supervisor id

Operator Id: Enter operator id who will be operating the pouring process

Operator Name: Name will be auto fetched from operator id

Contractor: Enter contractor id

Contractor Name: Name will be auto fetched from Id

Branch Name: Enter the branch name

Casting Treatment: Select the casting treatment i.e. Fettling, Shot Blasting, etc Casting treatment can be done by both way like with pouring process or without pouring process

Casting Treatment Without Pouring: If casting treatment is with pouring then checkmark to this field. If this casting treatment is without pouring process then ignore to this field

Casting Treatment With Pouring

Step 1

Casting Treatment: Select the casting treatment.

Select Pouring: Select the pouring from dropdown list. User can select the multiple pouring for casting treatment

Step 2: Casting Item

Casting Item Code: Casting item will auto fetch from pattern master. This indicates the casting item code

Casting Item Name: This indicates the casting item name

Target Warehouse: Target warehouse name for product

Warehouse Available Quantity: This indicates the actual quantity of casting item

Remaining Treatment Quantity: This indicates the remaining quantity of casting item

All Goes to FR: After clicking this button all item will go for FR

Casting Treatment Without Pouring

Step 1: Make check mark to "Casting Treatment Without Pouring"

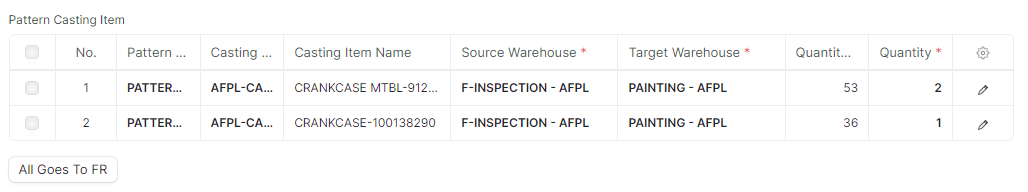

Step 2: Pattern Casting Item

Casting Item Code: Select the casting item code for casting treatment

Casting Item Name: As per casting item code item name will auto fetch

Pattern ID: Pattern id will auto fetch from casting item

Source Warehouse: Source warehouse of casting item

Target Warehouse: Target warehouse of casting item

Quantity Available In Warehouse: The actual quantity in warehouse of casting item

Quantity: This indicates the quantity of casting material we will use for casting treatment

All Goes to FR: After clicking this button all item will go for FR

Step 2: Raw Material

Item Code: Casting item code will be indicated here

Pattern ID: Pattern id will be auto fetched from casting item

Raw Item Code: If any case user needs any other raw materials for casting treatment then user can add on pattern master.

Raw Item Name: Item name will be auto fetched from item code

Source Warehouse: Source warehouse of raw item

Required Quantity: Required quantity of raw item

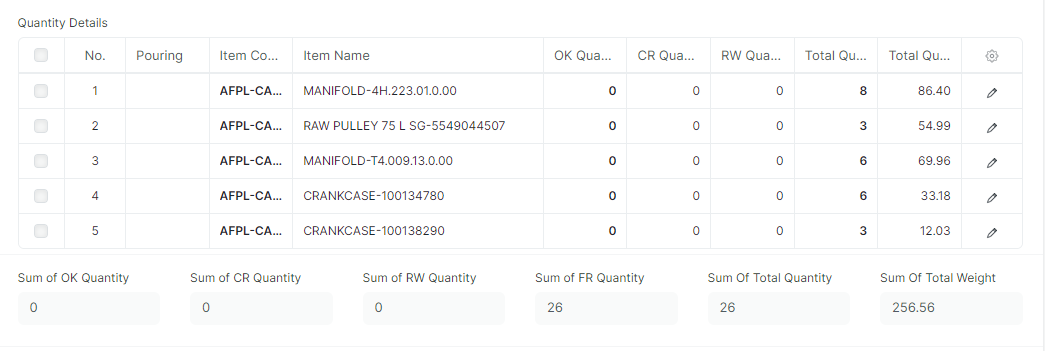

Step 3: Quantity Details

`

Pouring: This indicates the pouring id for reference

Item Code: It shows the item id whose quality inspection is necessary

Item Name: Item name will be auto fetched from item id

OK Quantity: This indicates that quantity after quality inspection of casting item. OK quantity shows casting item is ready to delivery

CR Quantity: CR quantity shows casting item has casting rejection

RW Quantity: RW quantity shows casting item has rework

FR Quantity: FR quantity shows casting item has foundry rejection

Sum of OK Quantity: This indicates the total quantity of OK quantity items.

Sum of CR Quantity: This indicates the total quantity of CR quantity items

Sum of RW Quantity: This indicates the total quantity of RW quantity items

Sum of FR Quantity: This indicates the total quantity of FR quantity items

Sum Of Total Quantity: This indicates the total quantity of quality inspection of casting item.

Sum Of Total Weight: This indicates the total weight of quality inspection of casting item.

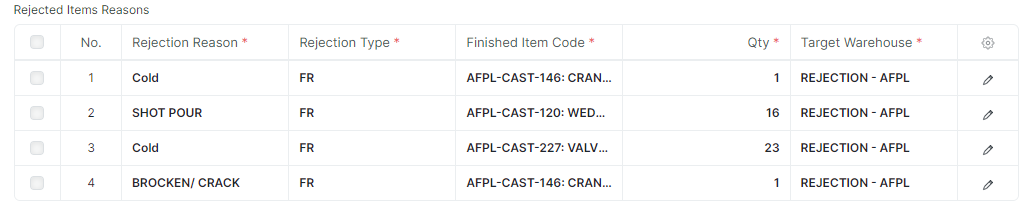

Step 4: Rejection Items Reasons

Rejection Reason: After the quality inspection of casting item click on "Get Rejection". All the rejections will auto displayed in "Rejection Items Reasons" table. This column indicates the reasons of rejections of casting items

Rejection Type: This column indicates the rejection type of casting items i.e. CR, FR, CW, etc.

Finished Item Code: This column indicates the finished item of casting material

Qty: This column indicates the total quantity of rejected items of casting material with respect to rejection type

Target Warehouse: This column indicates the target warehouse of rejected casting material

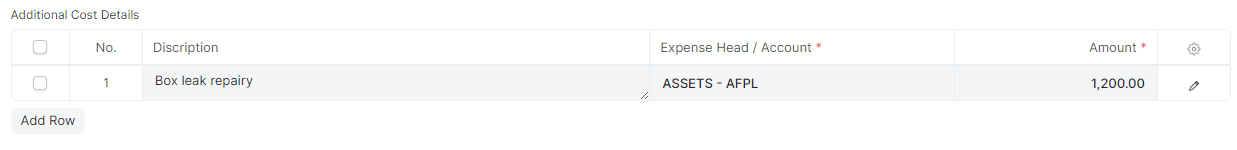

Step 5: Additional Cost Details

Descriptions: Enter the description of additional cost of casting treatment except production cost

Expense Head / Account: Enter the expenses head accounts name

Amount: Enter the total amount of expenses

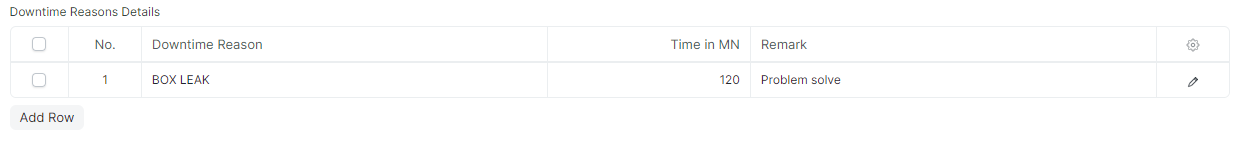

Step 6: Downtime Reasons Details

Downtime Reason: Select the reason of downtime from dropdown list

Time in MN: Enter the total downtime time in minutes

Remark: Enter the remark about the downtime time or reason

Step 7: Click on "Save"