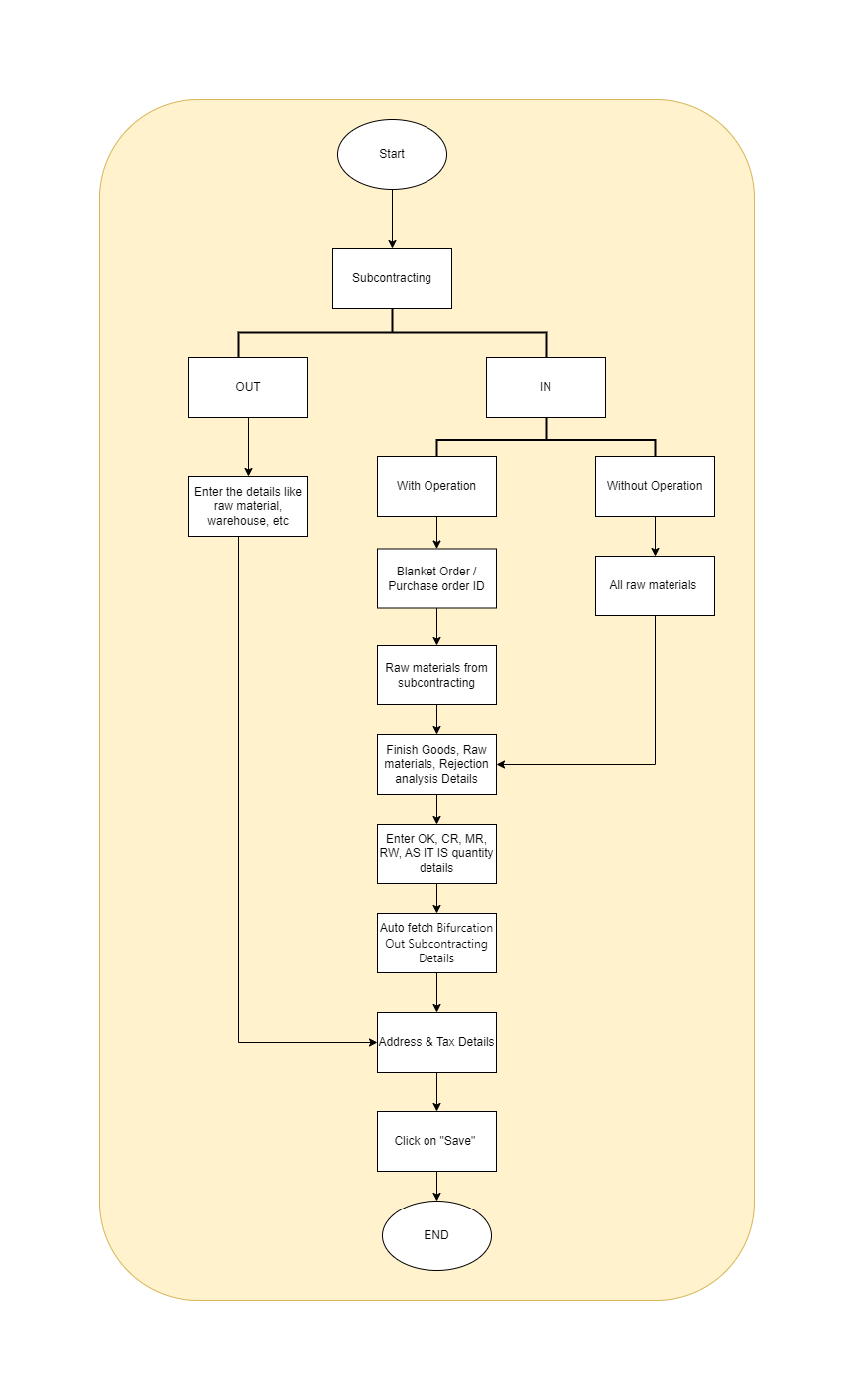

Subcontracting Process

Foundry > Subcontracting

Steps to create Subcontracting

Step 1: Go to subcontracting list and click on "Add Subcontracting"

Step 2:

Series: Select the series as per the requirement

Company: Select the company name from dropdown

Supervisor Id: Enter the supervisor id of who will be supervising the casting treatment

Supervisor Name: Name will be auto fetched from supervisor id

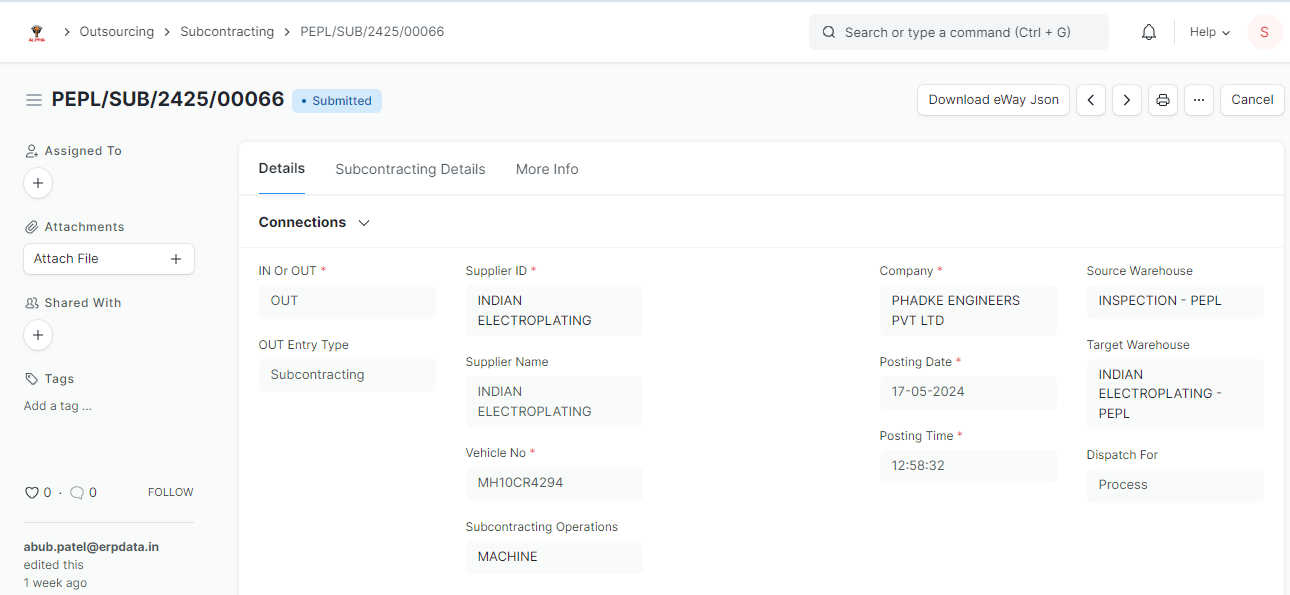

Vehicle No: Enter the vehicle number which will be used to transport the subcontracting material

Posting Date & Time: Posting date and time will be auto filled as per real time

Source Warehouse: Enter the source warehouse of raw material

Target Warehouse: Enter the target warehouse of finish item

Dispatch For: Enter the dispatch reason like process or rework

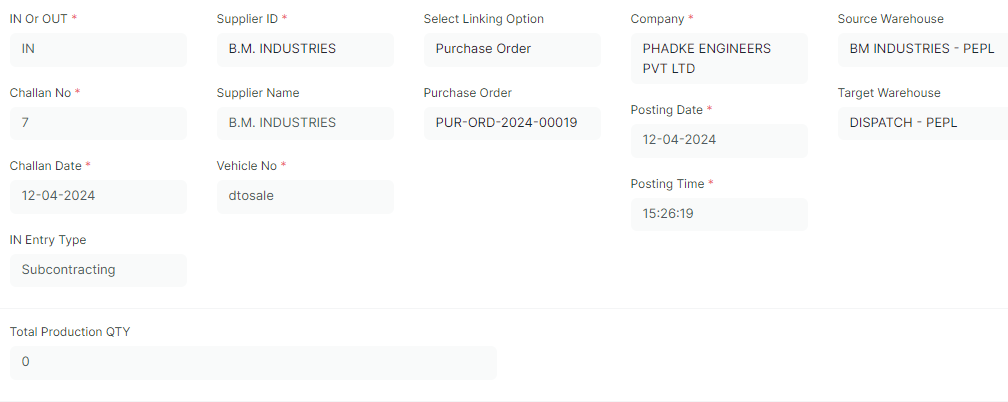

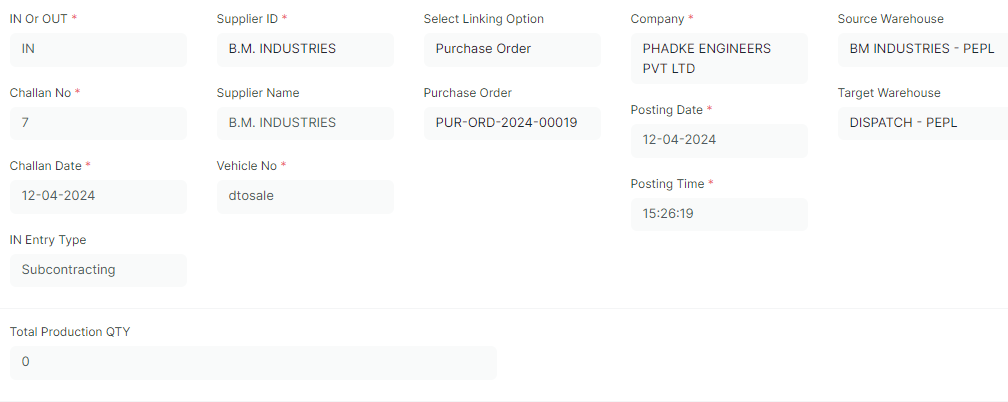

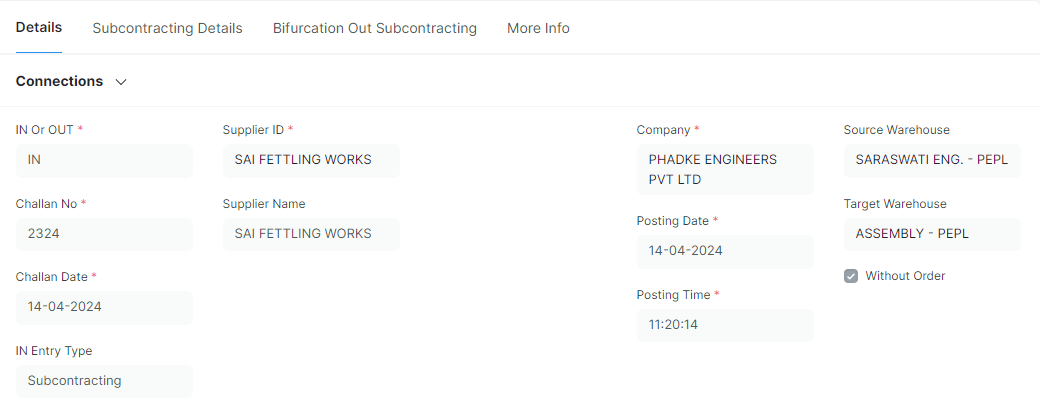

IN Or OUT: Enter the subcontracting type. If material is going for subcontracting then select as "OUT". If material is received after then please select as "IN"

Step 3.1: If subcontracting type is "OUT"

Item Group: Select the item group for subcontracting item

Subcontracting Operations: Select the subcontracting operation type

Raw Item Code: Enter the raw item code which is sent for subcontracting

Raw Item Name: Item name will be auto fetched from item code

Source Warehouse: Enter the source warehouse of raw material

Target Warehouse: Enter the finish product warehouse

Available Quantity: Available quantity of raw material from source warehouse will auto fetched

Total Production QTY: Total quantity will auto calculate as per entered data

Step 3.1: If subcontracting type is "IN"

Challan No: Enter delivery challan number

Challan Date: Enter Challan date

IN Entry Type: Select type of entry

Step 3.1.1: Subcontracting with order

Check mark on "With Order"

Select Linking Option: Select the order type as blanket order or purchase order

Blanket Order / Purchase Order: Select the order id

Step 3.1.2: Subcontracting without order

Remove check mark of subcontracting with order

All raw materials of subcontracted materials will shown in "Out Subcontracting list"

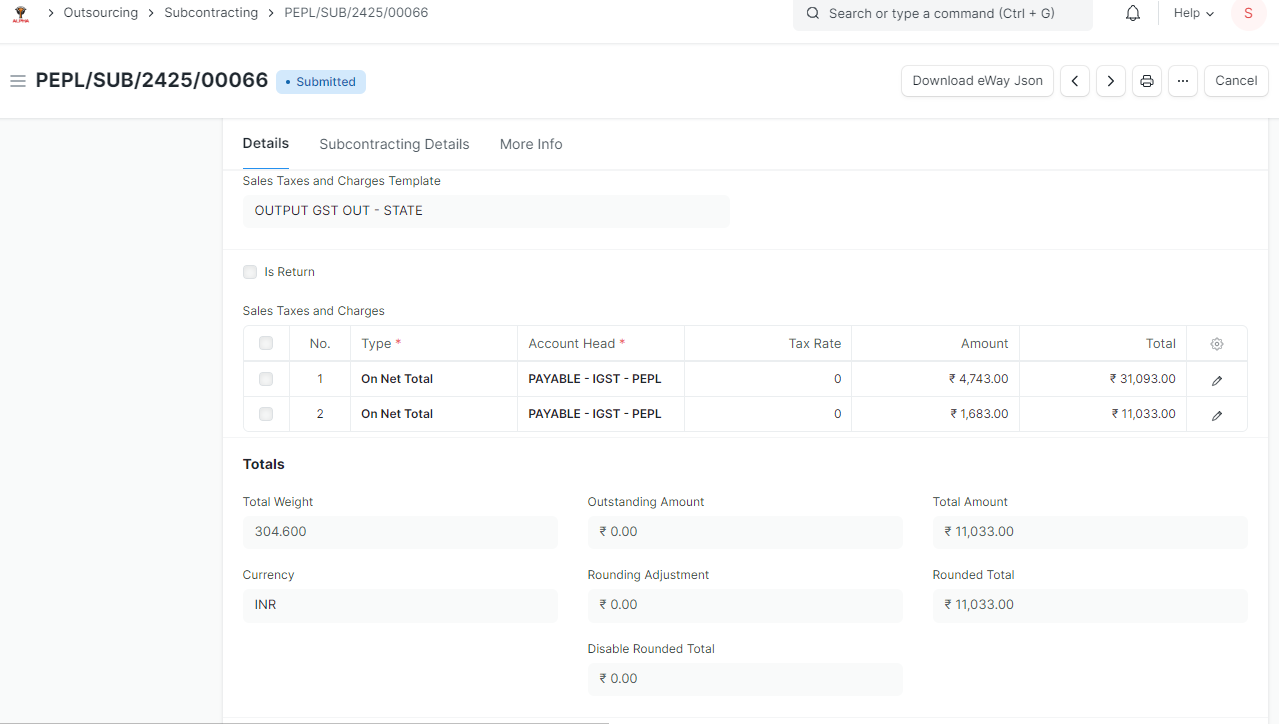

Step 4: Taxes and Charges

Sales Taxes and Charges Template: Auto select as per address. System will auto calculate the GST cost as per template

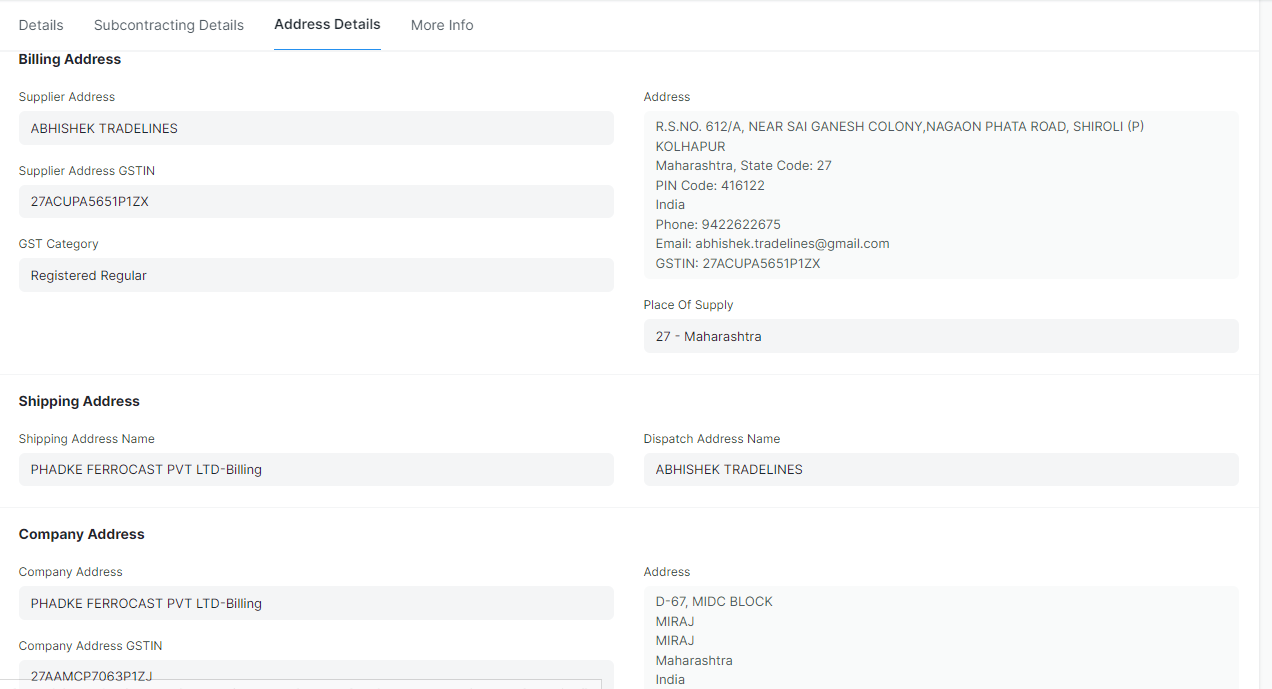

Step 5: Address Details

Billing & Shipping Address: Billing address will be auto fetched from address doctype of supplier

Company Address: Company address will be auto fetched from company setup

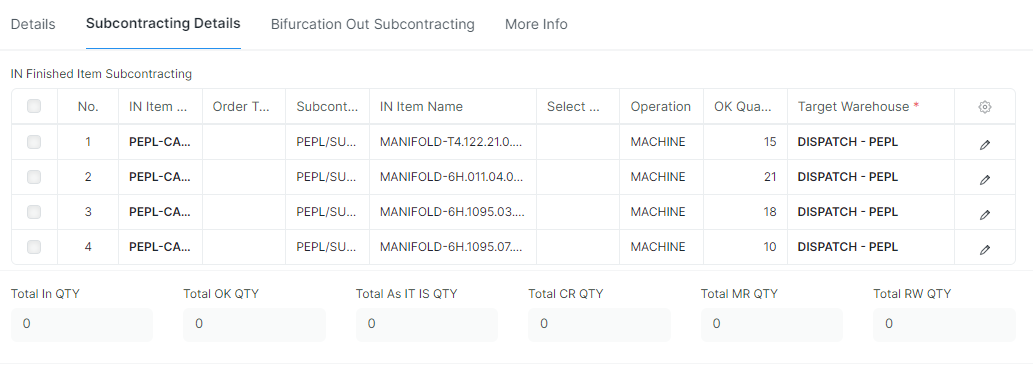

Step 6: Subcontracting Details (Enter this data only if subcontracting type is "IN")

IN Finished Item Subcontracting (For Finish items)

IN Item Code, IN Item Name, Subcontracting, Operation : This data will auto fetched from details tab.

OK QTY: Enter the OK quantity count of "IN" quantity

CR QTY: Enter the CR quantity count of "IN" quantity

MR QTY: Enter the MR quantity count of "IN" quantity

RW QTY: Enter the RW quantity count of "IN" quantity

Target Warehouse: Enter the target warehouse for each item

Total In, OK, CR, MR, RW, AS IT IS QTY: Auto calculate the total count of "IN" quantities

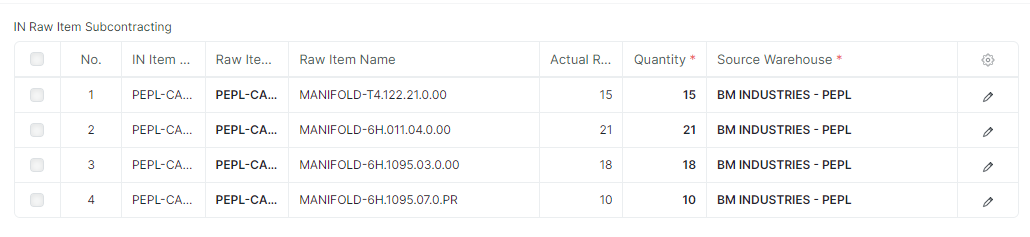

IN Raw Item Subcontracting (For Raw Material)

IN Item Code, Raw Item Code, Raw Item Name, Source Warehouse, Actual Required Quantity, Weight Per Unit, Total Required Weight: This data will be auto fetched from details tab.

Quantity: Enter the quantity of received raw material

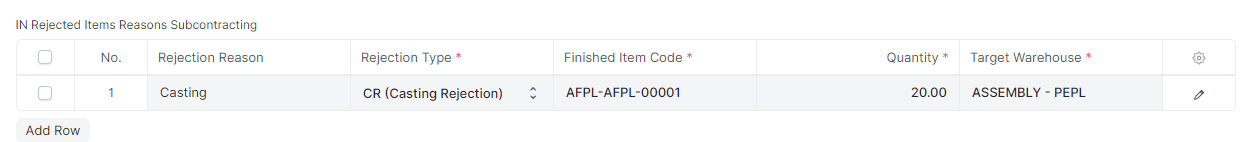

IN Rejected Items Reasons Subcontracting (Rejection Reasons)

Rejection Reason: Enter the rejection reason

Rejection Type: Enter type of rejection

Finished Item Code: Enter finished item code of rejection

Raw Item Code: Enter raw item code for finished product

Quantity: Enter the rejected quantity

Source Warehouse: Enter the source warehouse of raw material

Target Warehouse: Enter the target warehouse of finished material

Weight Per Unit: This will be auto calculated as per per quantity of item

Total Rejected Weight: Total weight quantity will be auto calculated from weight per unit.

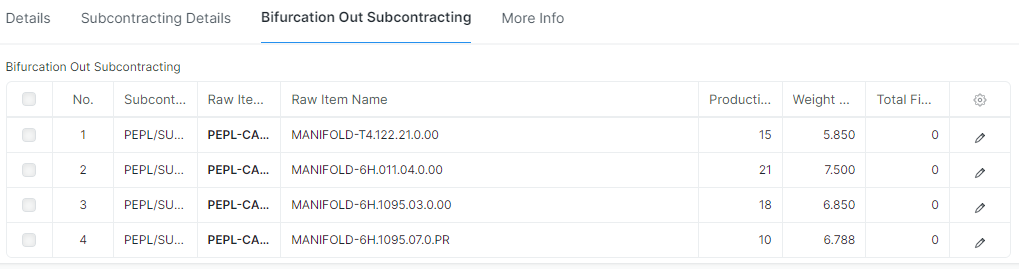

Step 7: Bifurcation Out Subcontracting

Subcontracting, Raw material details, OK, CR, MR, RW, Production (out, remaining, done item) details, Weight Per Unit, Total Finished Weight: This data is auto fetched from previous info