Manufacturing Job Card

Think of manufacturing job cards as the passport that follows your product through every step of its creation journey, collecting important stamps and information along the way.

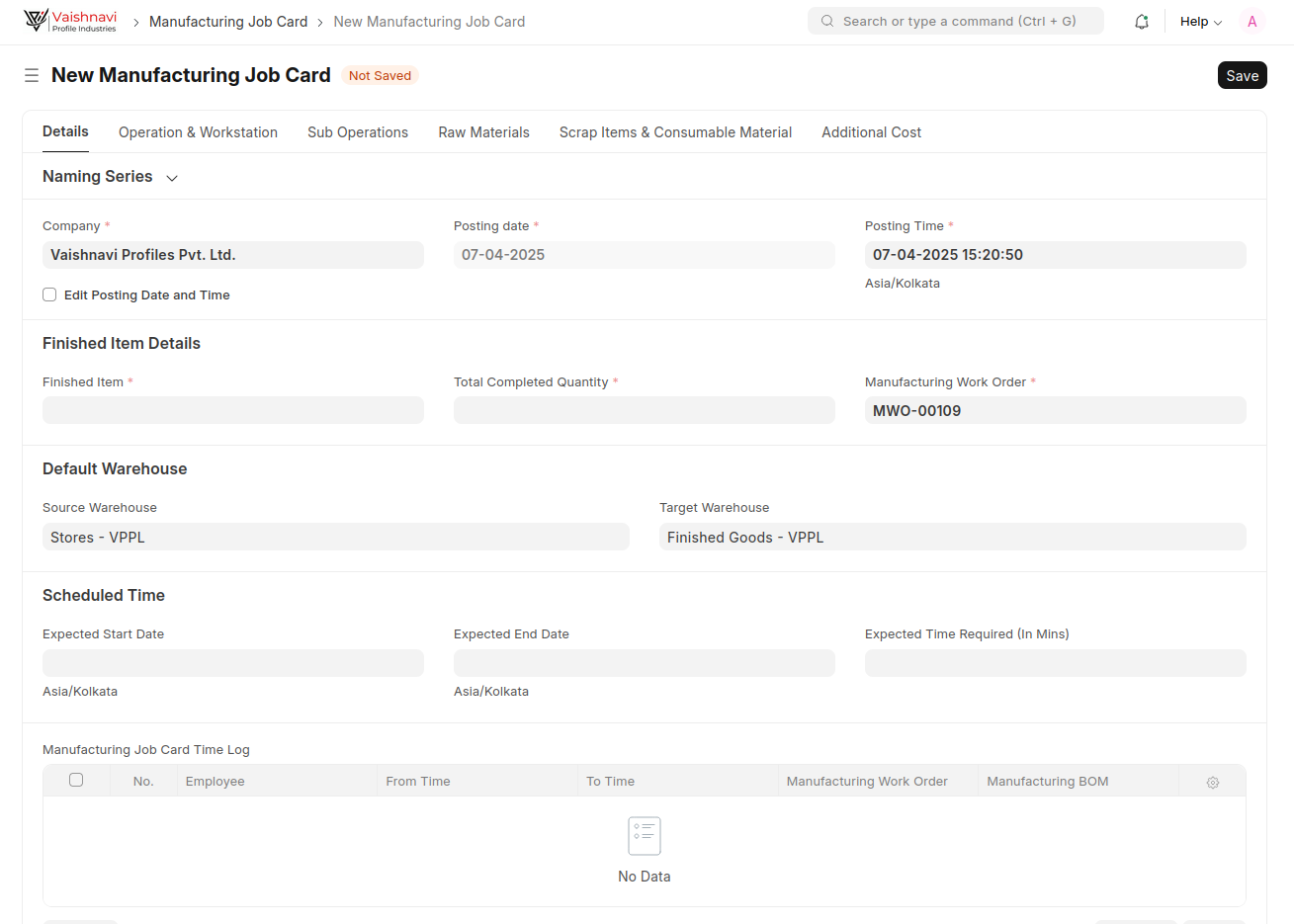

Step 1: Finished Item Details:

When creating a Manufacturing job card from a Manufacturing work order, the system automatically fetches:

Finished item details,Default warehouse information,Scheduled time parameters.

These details are pulled directly from the associated Manufacturing Work Order, reducing manual data entry and ensuring consistency.

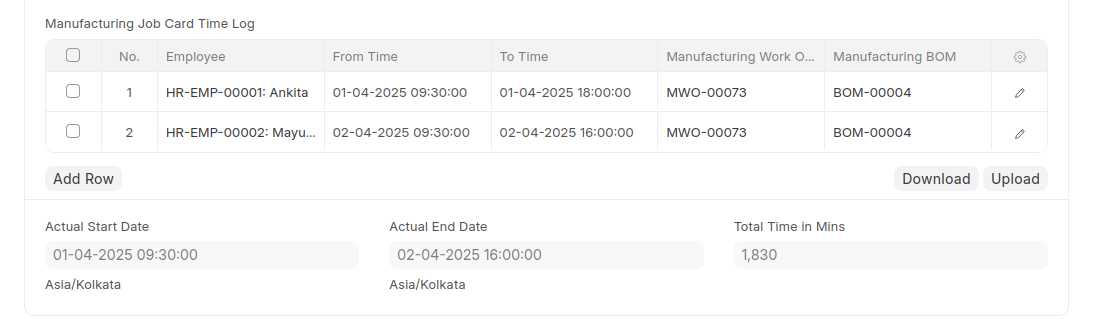

Step 2: Manufacturing Job Card Time Log:

Track the time spent by employees on specific manufacturing tasks

Record start and end times for operations

Link employee activities to specific work orders and BOMs

Calculate total time required for production

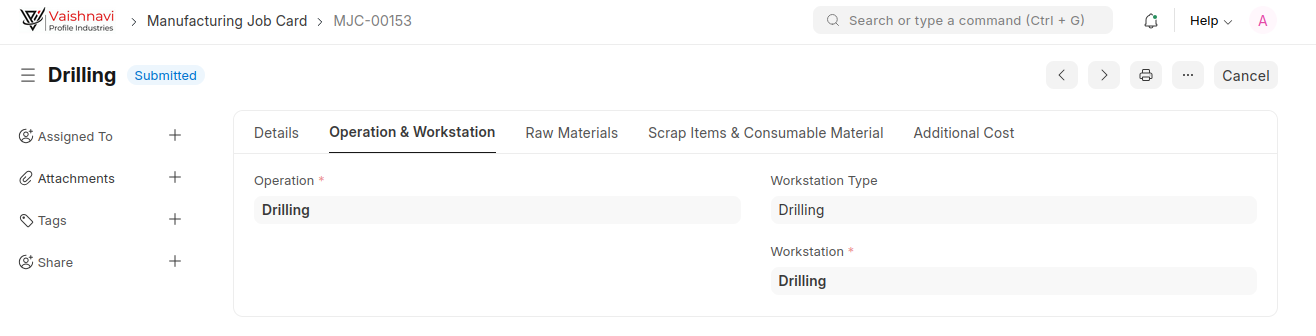

Step 3: Operation & Workstation Tab:

Ensure proper tracking of where operations are performed

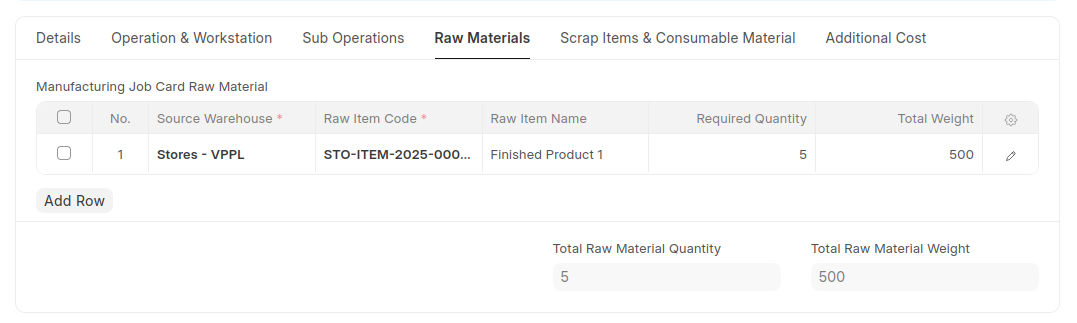

Step 4: Raw Materials Tab:

Displays raw materials required for the manufacturing process

Information is fetched from the Manufacturing work order's raw material section

Tracks quantities, source warehouse, and total weight

Similarly, the Scrap Items & Consumable Material tab shows data about scrap and consumables used

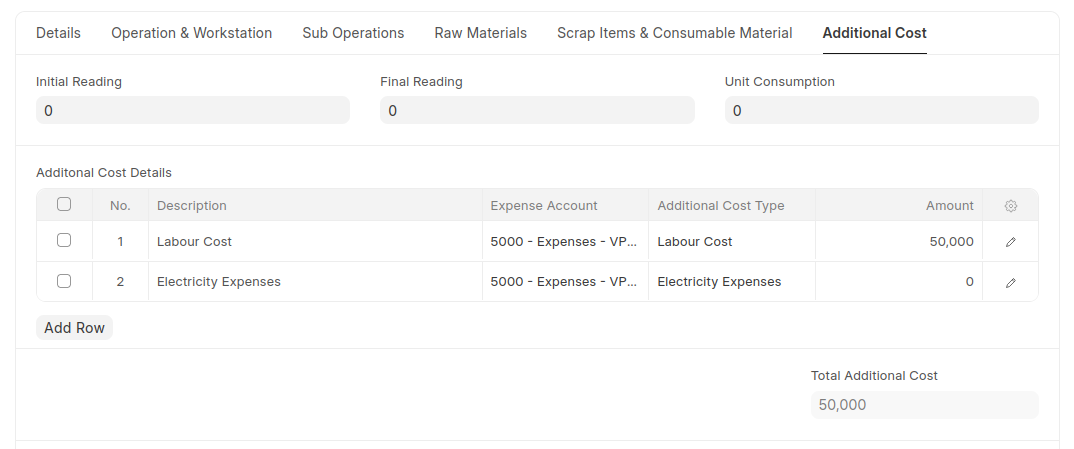

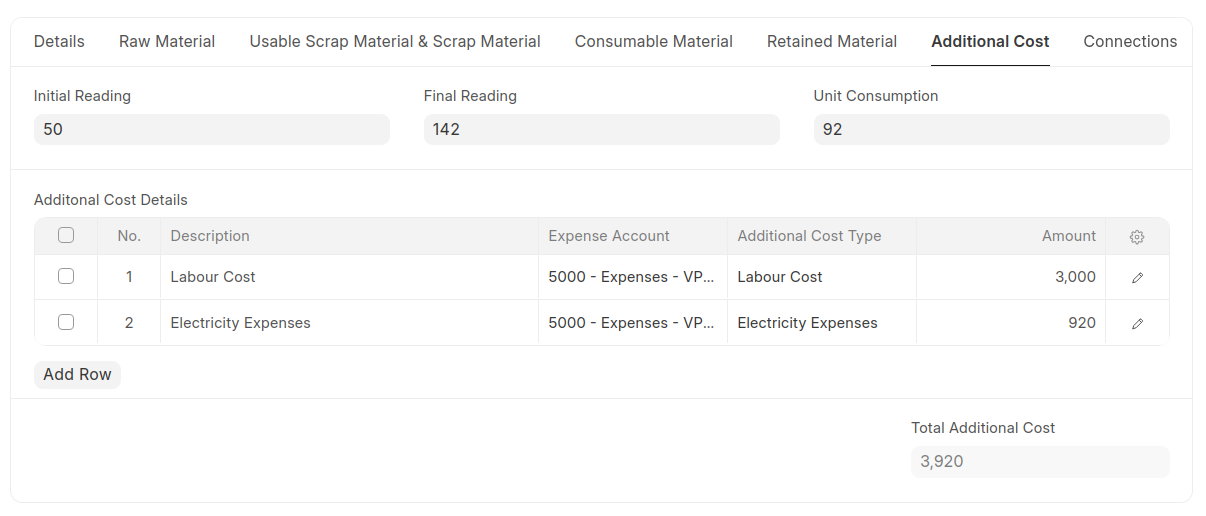

Step 5: Additional Cost Tab:

Record non-material costs associated with the manufacturing process

Track labor costs, electricity expenses, and other overhead costs

Calculate total additional costs for accurate product costing

After submitting a Manufacturing Job Card, the system automatically generates a Stock Entry document that captures the following...

This Stock Entry document serves as the official record of inventory movements and value changes resulting from the Manufacturing operation, ensuring proper tracking of materials and costs throughout the manufacturing process.