Pattern Master

Home > Foundry > Pattern Master

Steps to create Pattern Master

Prerequisite for Pattern Master:

Production Details

Casting Items

Core Items

Weight Details

Sand Item Details

Step 1: Go to Pattern Master and click on "Add Pattern Master"

Series: Series will be auto selected as per doctype

Company: Select the company name from dropdown

Pattern ID: We have to create a new item for each pattern. Enter the new pattern id. This field only allows the items whose item group is a pattern.

Pattern Name: Pattern name will be auto fetched from pattern id.

Drawing Number: Enter the drawing number of pattern

Pattern Owner: Pattern will be decided by the customer or the company will decide how the pattern should be

Customer Name: If pattern is decided by customer then enter the customer name

Quality Type: Select the quality type of pattern i.e. Not applicable, Not required, etc.

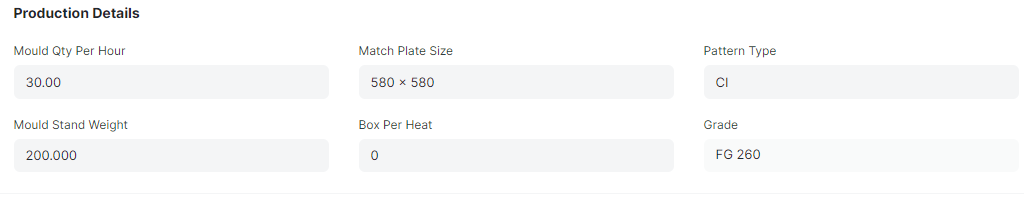

Step 2: Production Details

Mould Quantity Per Hour: Enter the quantity of mould that are formed in one hour

Mould Stand weight:

Match Plate Size: Enter the pattern plate size

Pattern Type: Enter the pattern type

Box Per Heat:

Grade: Enter the grade for pattern

Pattern Life: Pattern life depends on number of items to be produced from this pattern. Enter the pattern life in number format

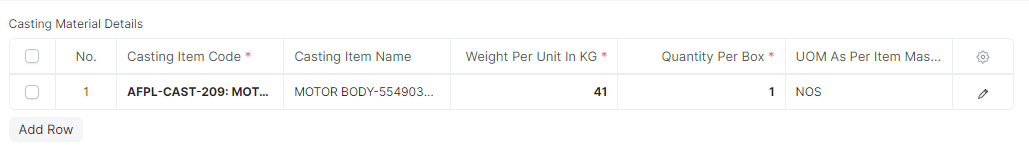

Step 3: Casting Material Details

Casting Item Code: Enter the casting item code which will use for casting

Casting Item Name: Item name will be auto fetched from item code

Weight Per Unit In Kg: Weight details will be auto fetched from item code

Quantity Per Box: Enter the quantity of product after casting process

UOM: UOM of casting item

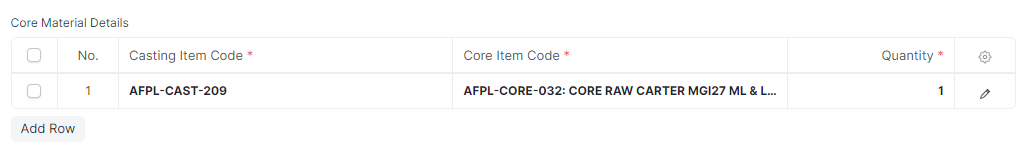

Step 4: Core Item Details

Casting Item Code: Enter data as per above. This allows you multiple core for single casting

Core Item Code: Enter the core item code. This only allows the core item whose item group is core.

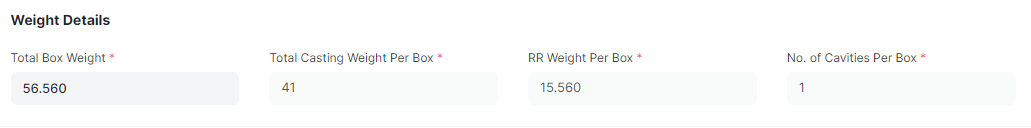

Step 5: Weight Details

Total Box Weight: Enter the mould box weight.

Total Casting Weight Per Box: This value will be auto calculated from total box weight

RR Weight Per Box: The RR weight will be calculated from total box weight

No. of Cavities Per Box: The number of quantity of casting per box. This will be calculated from total weight.

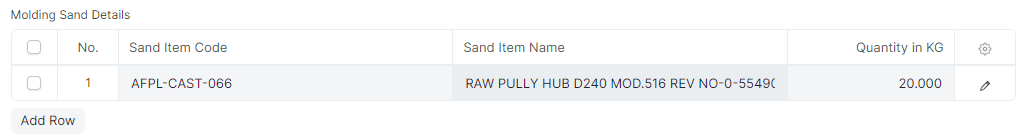

Step 6: Moulding Sand Details

Sand Item Code: Enter the sand item code

Sand Item Name: Sand item name will be auto fetched from item code

Quantity in KG: Enter the quantity of sand item in kg format.

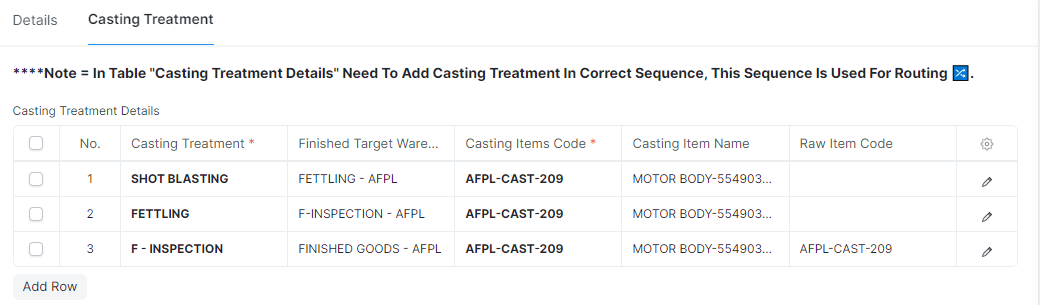

Step 7: Casting Treatment

*Note: Please enter casting treatments in correct sequence, This sequence will be used for routing as well as casting treatment

*Note: Please enter casting treatments in correct sequence, This sequence will be used for routing as well as casting treatment

Casting Treatment: This column indicates the casting treatment for pattern i.e. shot blasting, Fettling, etc.

Finished Target Warehouse: This warehouse indicate target warehouse for casting treatment after casting treatment process

Casting Items Code: Enter the casting item id which used in casting treatment with respect to that casting treatment

Casting Item Name: Item name will auto fetch from casting item id

Raw Item Code: If any casting treatment needed other than raw materials then add that item id in this field. This Raw material will shown on casting treatment process.