Manufacturing BOM

Think of a Manufacturing Bill of Materials (BOM) as your product's complete recipe and cooking instructions.Just like you can't bake a cake without knowing all ingredients and steps, you can't efficiently manufacture products without a detailed BOM.

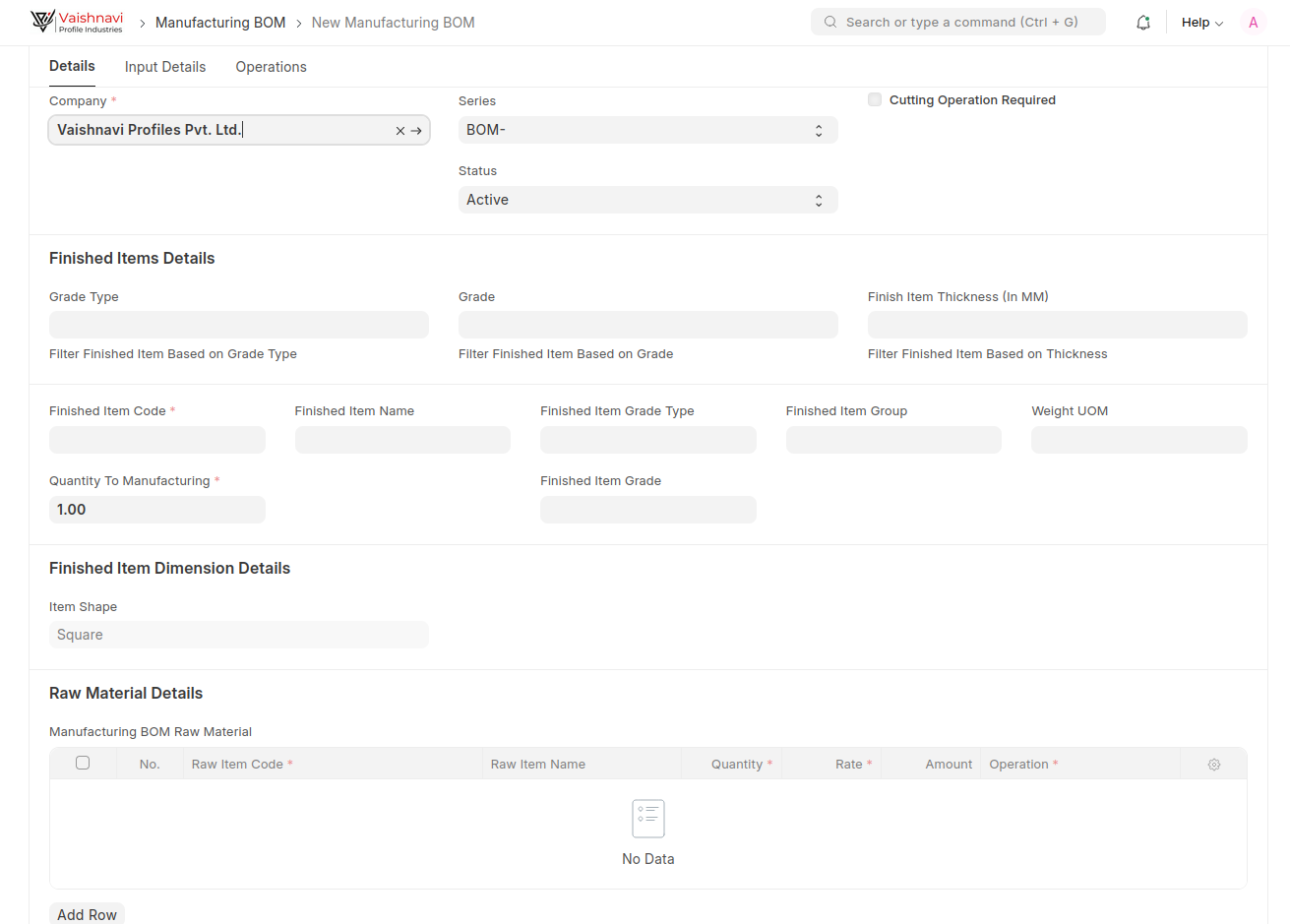

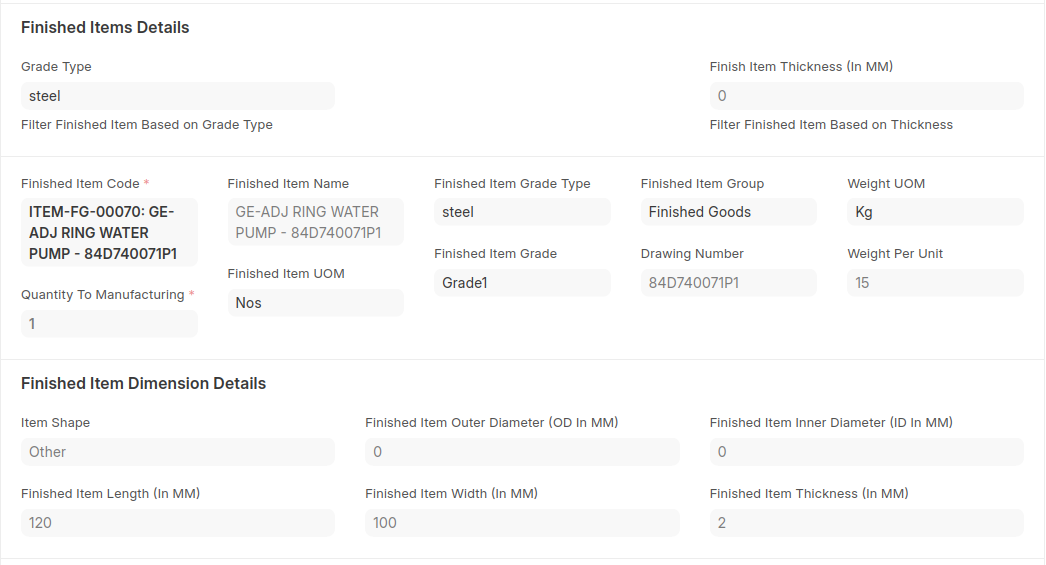

Step 1: Filling Finished Items Details

Enter the Grade Type (e.g., steel)

Enter the Grade (e.g.. A36, A572)

Specify Finish Item Thickness (in MM)

Once entered Finished Item Code, the system will automatically populate related fields like(weight per unit,dimension Details...etc)

Enter Quantity To Manufacture (marked with *)

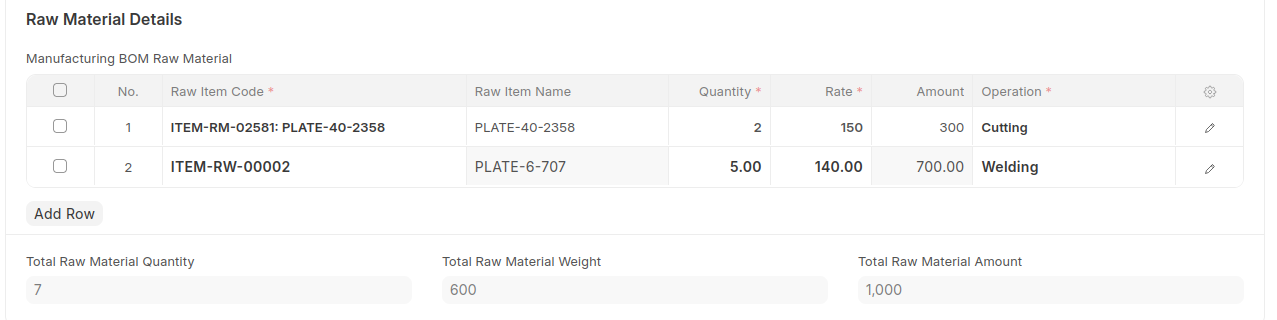

Step 2: Adding Raw Materials

1) Under Manufacturing BOM Raw Material, add necessary materials

Enter Raw Item Code, Quantity, Specify Rate to calculate Amount automatically.

Select the appropriate Operation(e.g.,Assembly,Drilling, Cutting....etc)

System will automatically populate its Total Raw Material Quantity, Weight and Amount.

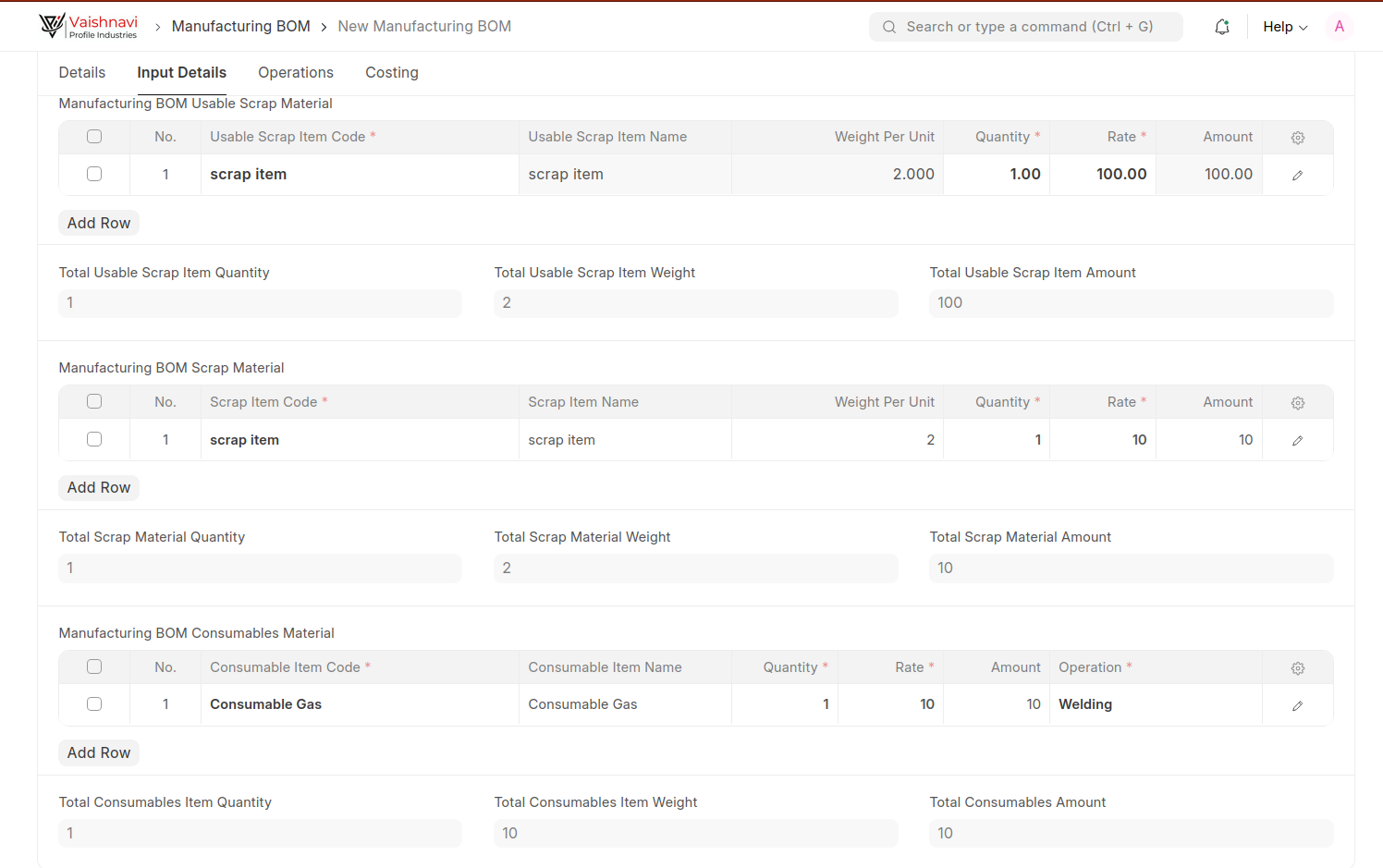

Step 3: Input Details Tab

Switch to the Input Details tab to fill in additional material information:

Manufacturing BOM Usable Scrap Material:

Enter Usable Scrap Item Code, Specify Required Quantity, Specify Rate to calculate Amount automatically.

Select the appropriate Operation(e.g.,Assembly,Drilling, Cutting....etc).

once you Entered Usable Scrap Item Code, system will automatically populate Dimension Details.

System will automatically populate its Total l Usable Scrap Item Quantity, Weight and Amount.

similarly, for Manufacturing BOM Scrap Material, Manufacturing BOM Consumables Material.

Step 4: Operations Tab

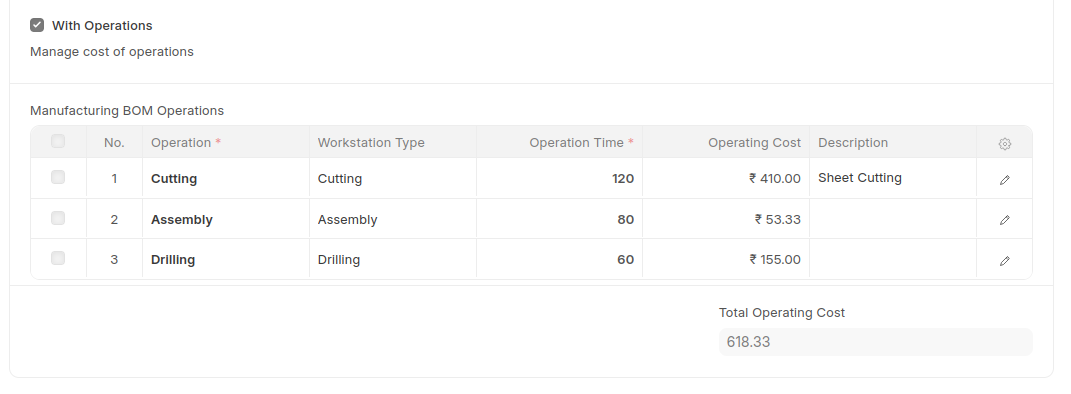

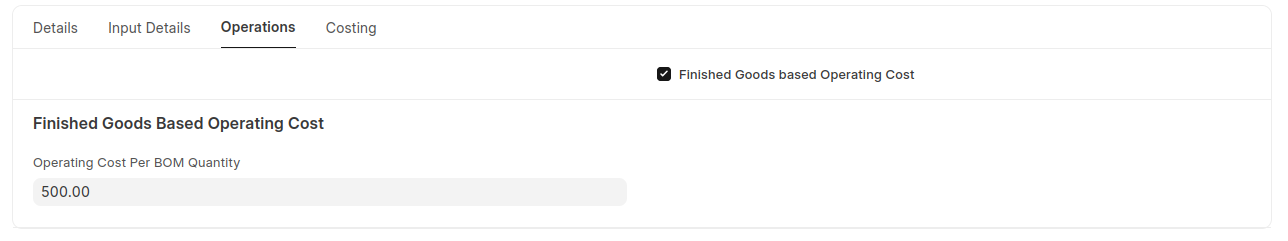

Navigate to the Operations tab to define manufacturing operations:

If Check "With Operations" to manage cost of operations, Select the appropriate Routing in the dropdown field And Add Manufacturing BOM Operations:(e.g., Drilling, Welding, Cutting).

If Check "Finished Goods based Operating Cost" , fill the Operating Cost Per BOM Quantity.

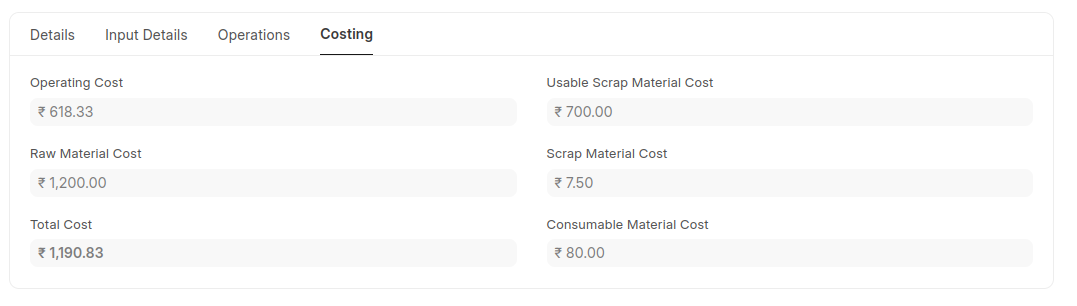

Step 4: Costing Tab

Review the Total Operating Cost

Total Operating Cost include Operating Cost,Raw Material Cost,Usable Scrap Material Cost,Scrap Material Cost,Consumable Material Cost.

Step 5: Save and Finalize

Click the Save button in the upper right corner

The system will validate all entries

Once saved, the status will change from "Not Saved" to saved

In simple terms, a Manufacturing BOM gives you control, clarity, and confidence in your manufacturing process. Streamlined Production, Better Decision Making , Cost Control...etc