Process Definition

Efficiently streamline the distillery production process from molasses to high-quality products like extra neutral alcohol (ENA), industrial grade (IS), rectified spirit (RS), and ethanol. Maintain meticulous bookkeeping for daily operations. Implement robust inventory management to track molasses, ENA, IS, RS, and ethanol levels, optimizing stock movements between storage locations.

Record all production costs meticulously, including raw material, labor, and overhead expenses. Use advanced cost allocation to assign expenses to specific orders and calculate precise product costs. Generate financial reports for insights into production costs, revenues, and profitability.

For Molasses Procurement and Storage, establish streamlined processes for procuring from sugar cane processing plants or molasses storage tanks. Utilize stock transfers for replenishing distillery storage silos.

Execute planned molasses transfers to the Work-in-Progress (WIP) stage, processing raw materials into finished products efficiently

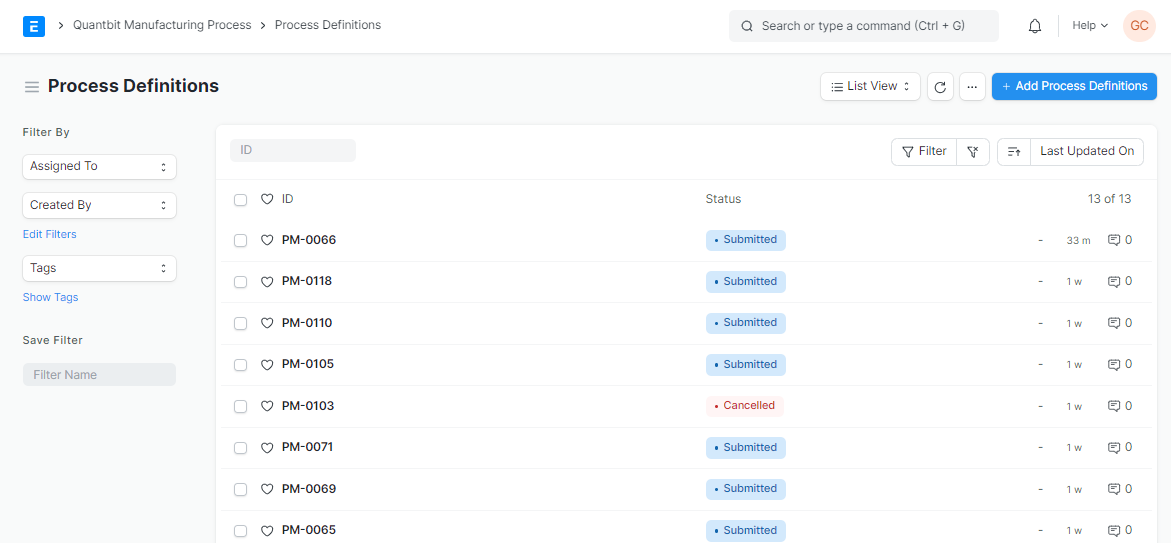

Steps to create Process Definition

Home > Process Definition

Step 1: Go to process definitions list and click on "Add new Process Definitions"

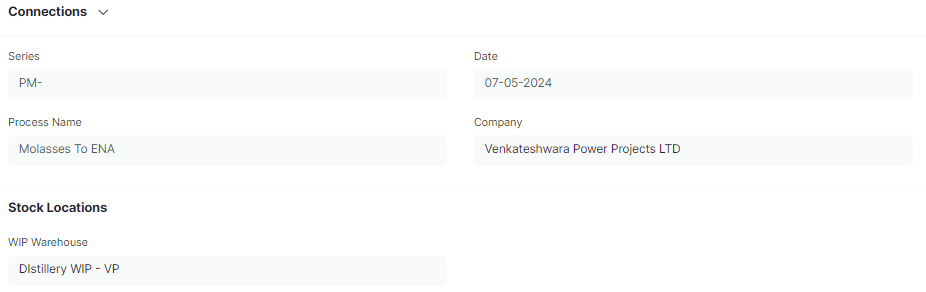

Series: Series will auto select the as per doctype

Date: Date will auto filled from current date in date format "DD/MM/YYYY"

Company: As per session default company name will auto filled

Process Name: Enter the process name like molasses, etc.

WIP Warehouse: Enter the work in progress warehouse name

Set Source Warehouse: Enter the raw material warehouse from warehouse list

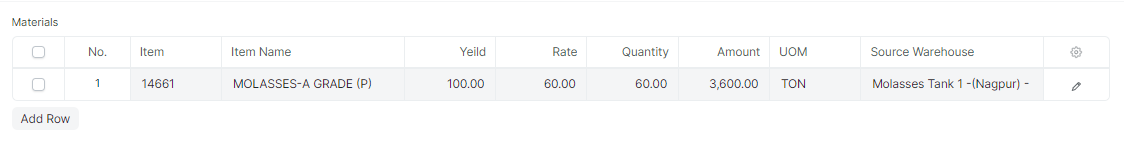

Step 2: Materials

Item: Add the raw materials item code

Item Name: Item name will auto fetch from item code

Yield: Enter the yield of raw material

Rate: Enter the rate per quantity

Quantity: Enter the quantity of raw material as per yield

UOM: UOM of raw material will auto fetch from item

Source Warehouse: Enter the finish products warehouse

Total Quantity: It indicates the total quantity of raw materials

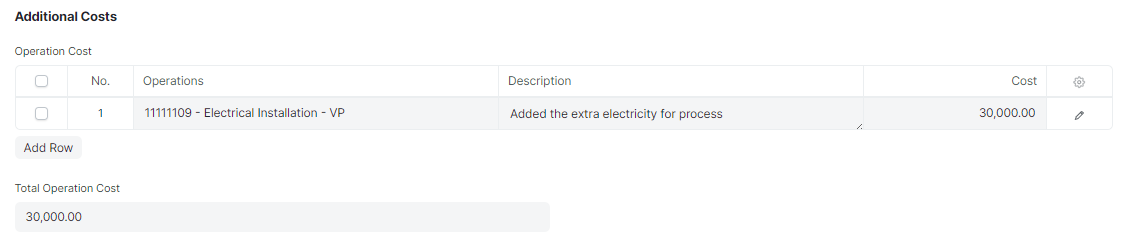

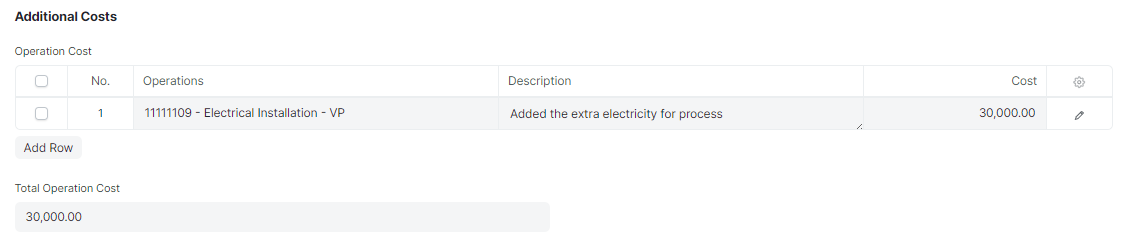

Step 3: Additional Costs

Operations: Enter the operation account name

Description: Enter the description of additional cost

Cost: Enter the additional cost amount

Total Operation Cost: It indicates the total operation cost amount

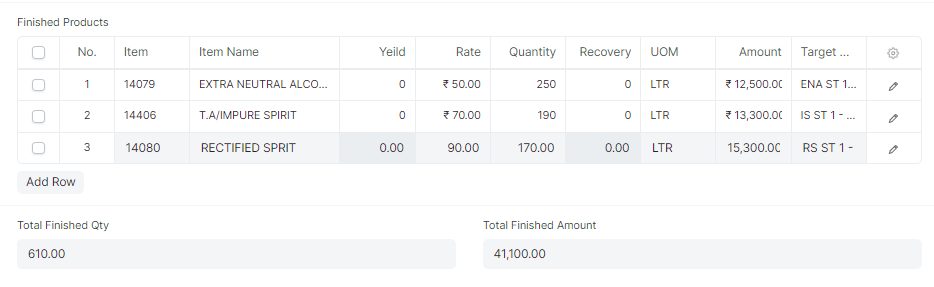

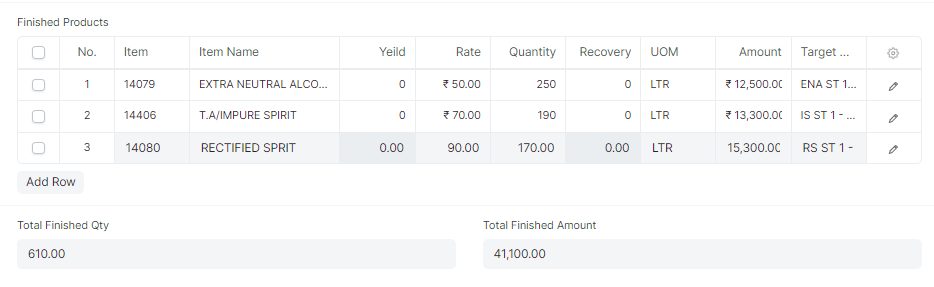

Step 4: Finished Products

Item: Add the finish products item code

Item Name: Item name will auto fetch from item code

Yield: Enter the yield of finish products

Rate: Enter the rate per quantity

Quantity: Enter the quantity of finish products as per yield

Amount: Total amount as per rate of quantity

Recovery: Enter the recover quantity of finished product

UOM: UOM of finish products will auto fetch from item

Target Warehouse: Enter the finish products target warehouse

Total Finished Qty: It calculates the total finished products quantity

Total Finished Amount: It calculates the total finished products amount

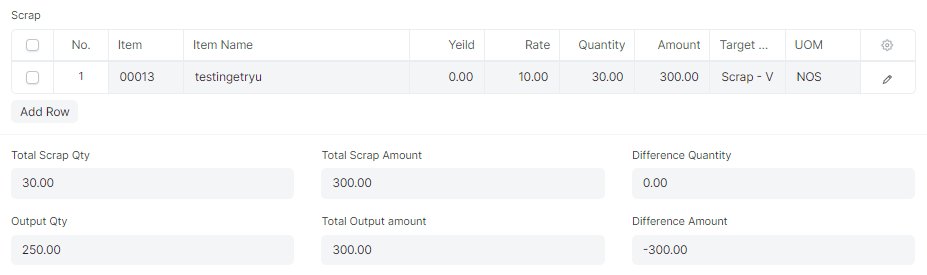

Step 5: Scrap Quantity

Item: Add the scrap products item code

Item Name: Item name will auto fetch from item code

Yield: Enter the yield of scrap products

Rate: Enter the rate per quantity

Quantity: Enter the quantity of scrap products as per yield

Amount: Total amount as per rate of quantity

UOM: UOM of scrap products will auto fetch from item

Target Warehouse: Enter the scrap products target warehouse

Total Scrap Qty: It indicates the calculation of total scarp quantity

Total Scrap Amount: It indicates the calculation of total scarp amount

Difference Quantity: It indicates the difference between scrap & actual output quantity

Output Qty: It indicates the output of process finished quantity

Total Output amount:

Difference Amount:

Step 5: Click on "Save"

Process Manufacturing

Home > Process Manufacturing

Step to create Process Manufacturing

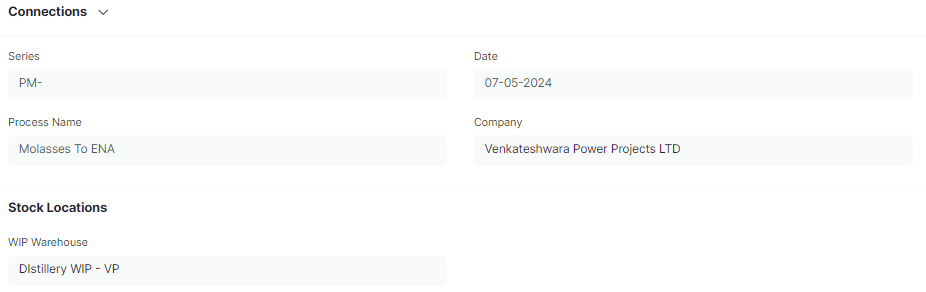

Step 1: Go to process manufacturing list and click on "Add new Process Manufacturing"

Series: Series will auto select the as per doctype

Date: Date will auto filled from current date in date format "DD/MM/YYYY"

Company: As per session default company name will auto filled

Process Name: Enter the process name like molasses to ENA, etc

Set Source Warehouse: Enter the raw material warehouse from warehouse list

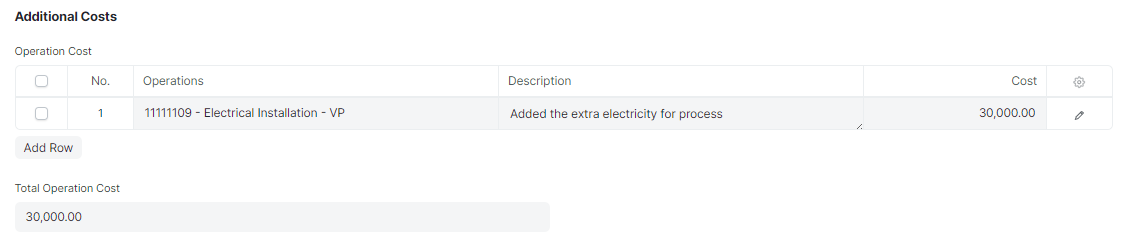

Step 3: Additional Costs

Operations:

Description: Enter the description of additional cost

Cost: Enter the additional cost amount

Total Operation Cost: It indicates the total operation cost amount

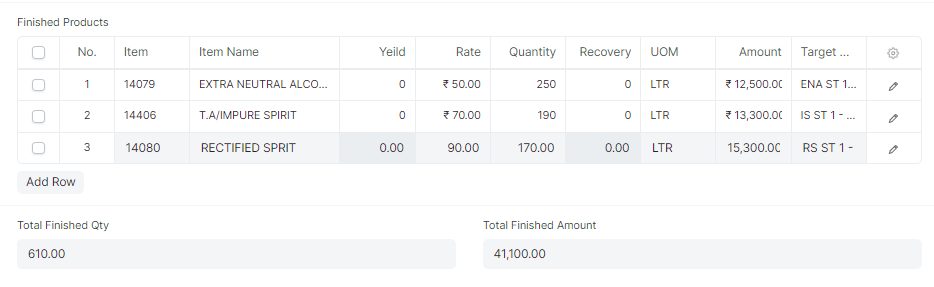

Step 4: Finished Products

Item: Add the finish products item code

Item Name: Item name will auto fetch from item code

Yield: Enter the yield of finish products

Rate: Enter the rate per quantity

Quantity: Enter the quantity of finish products as per yield

Amount: Total amount as per rate of quantity

Recovery: Enter the recover quantity of finished product

UOM: UOM of finish products will auto fetch from item

Target Warehouse: Enter the finish products target warehouse

Total Finished Qty: It calculates the total finished products quantity

Total Finished Amount: It calculates the total finished products amount

Step 5: Click on "Save"

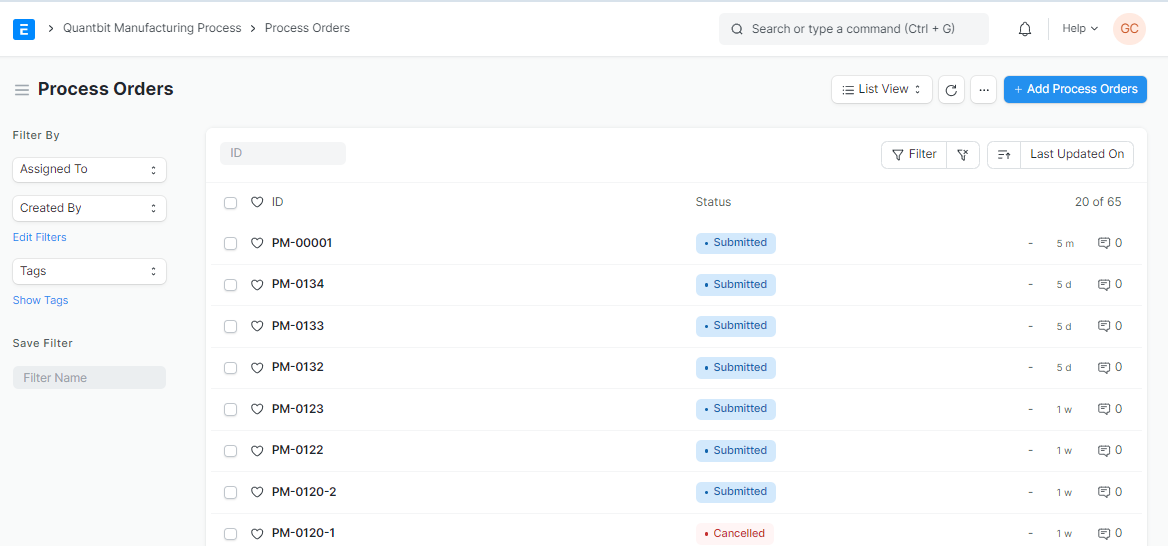

Process Order

Home > Process Order

Step to create Process Order

Step 1: Go to process definition entry, check in connection for " Process Order"

Step 1: Auto process order entry

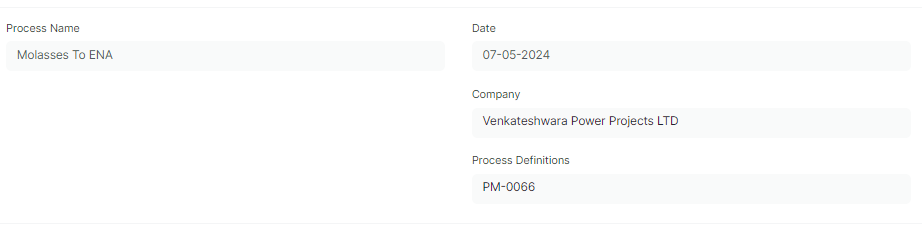

After submitting the process definition entry. System will generate the auto process order entry

Process Name: Process name fetched from process definitions

Date will auto filled from current date in date format "DD/MM/YYYY"

Company: As per session default company name will auto filled

Process Definitions: This field is for reference of process definition

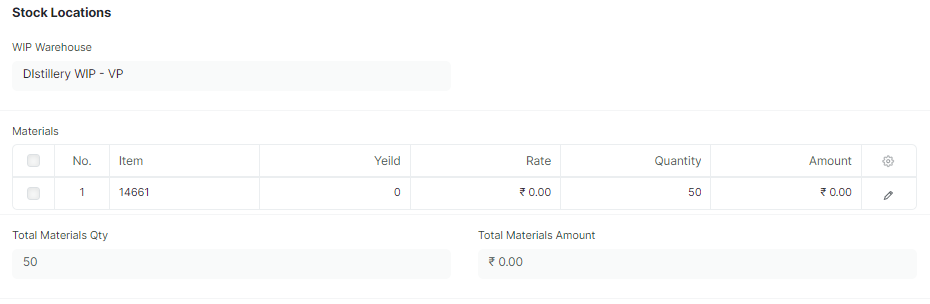

Step 2: Stock Location

WIP Warehouse: Enter the work in progress warehouse name

Item: Add the raw materials item code

Item Name: Item name will auto fetch from item code

Yield: Enter the yield of raw material

Rate: Enter the rate per quantity

Quantity: Enter the quantity of raw material as per yield

UOM: UOM of raw material will auto fetch from item

Source Warehouse: Enter the finish products warehouse

Total Quantity: It indicates the total quantity of raw materials

Step 3: Additional Costs

Operations:

Description: Enter the description of additional cost

Cost: Enter the additional cost amount

Total Operation Cost: It indicates the total operation cost amount

Step 4: Finished Products

Item: Add the finish products item code

Item Name: Item name will auto fetch from item code

Yield: Enter the yield of finish products

Rate: Enter the rate per quantity

Quantity: Enter the quantity of finish products as per yield

Amount: Total amount as per rate of quantity

Recovery: Enter the recover quantity of finished product

UOM: UOM of finish products will auto fetch from item

Target Warehouse: Enter the finish products target warehouse

Total Finished Qty: It calculates the total finished products quantity

Total Finished Amount: It calculates the total finished products amount

Step 5: Click on "Save"

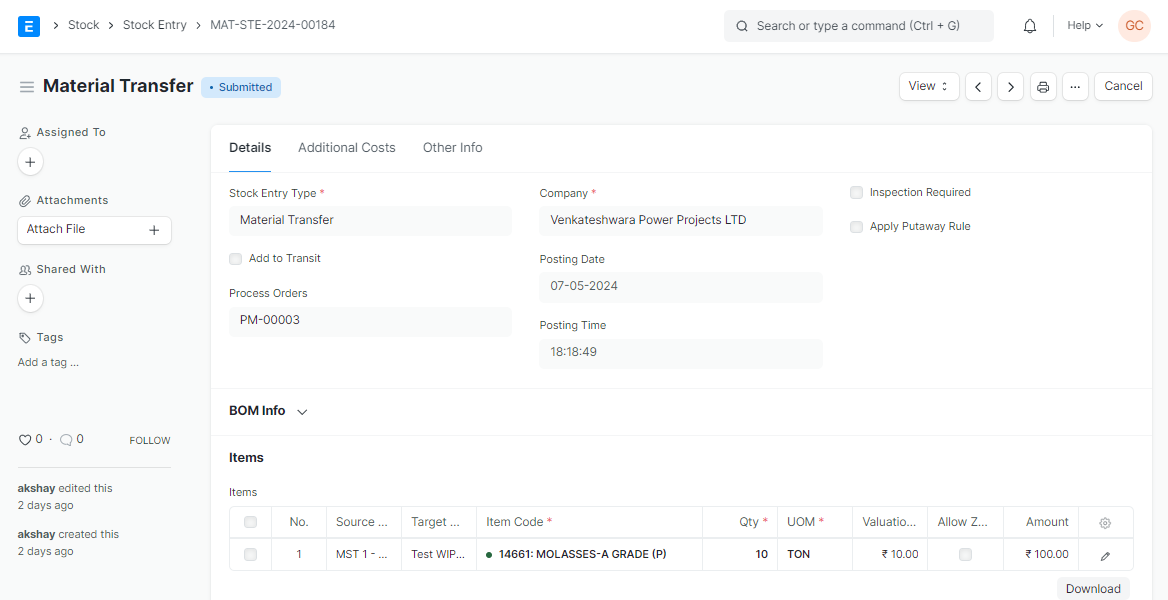

Step 6: Start the process order

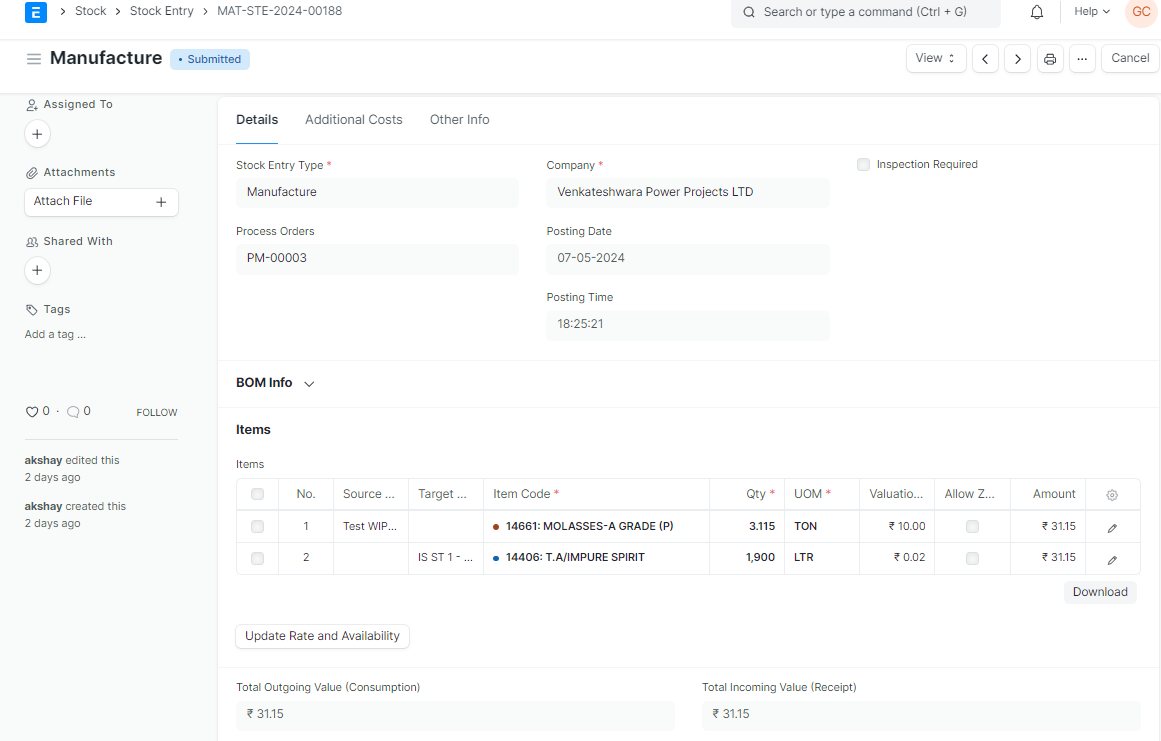

Click on "Start" button while starting the manufacturing process. After clicking the start button auto stock entry will generated for "Material Transfer"

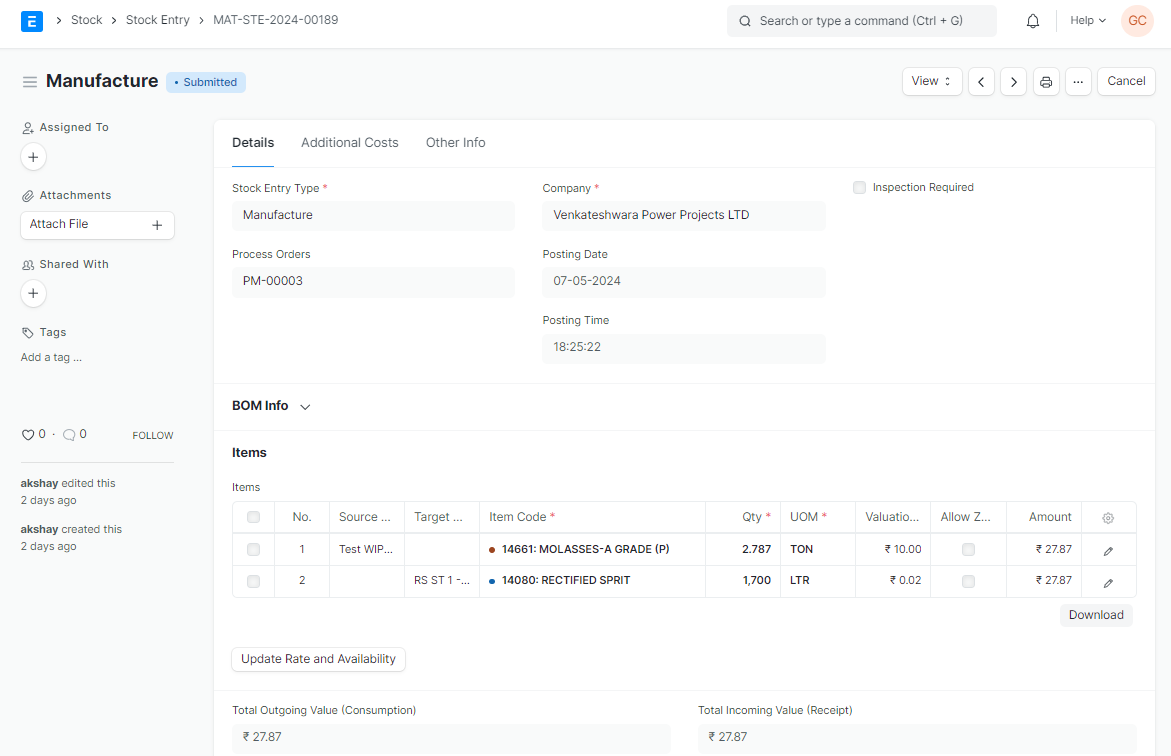

After the completing manufacturing process click on "Finish". Auto stock entry will updated as "Manufacture"

*Auto stock updates as "Finished Goods: Rectified Spirit" in respected warehouse

*Auto stock updates as "Finished Goods: Rectified Spirit" in respected warehouse

* Auto stock updates as "Finished Goods: ENA" in respected warehouse

* Auto stock updates as "Finished Goods: ENA" in respected warehouse

* Auto stock updates as "Finished Goods: Impure Spirit" in respected warehouse

* Auto stock updates as "Finished Goods: Impure Spirit" in respected warehouse