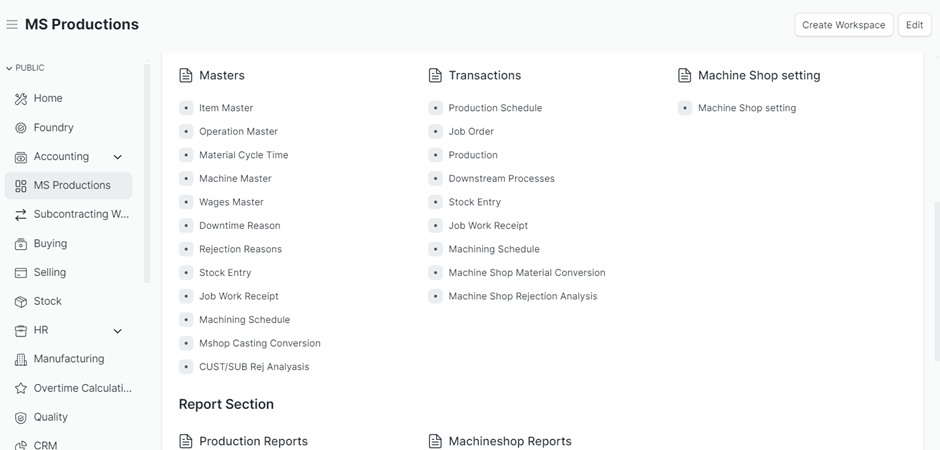

Machine Shop Masters

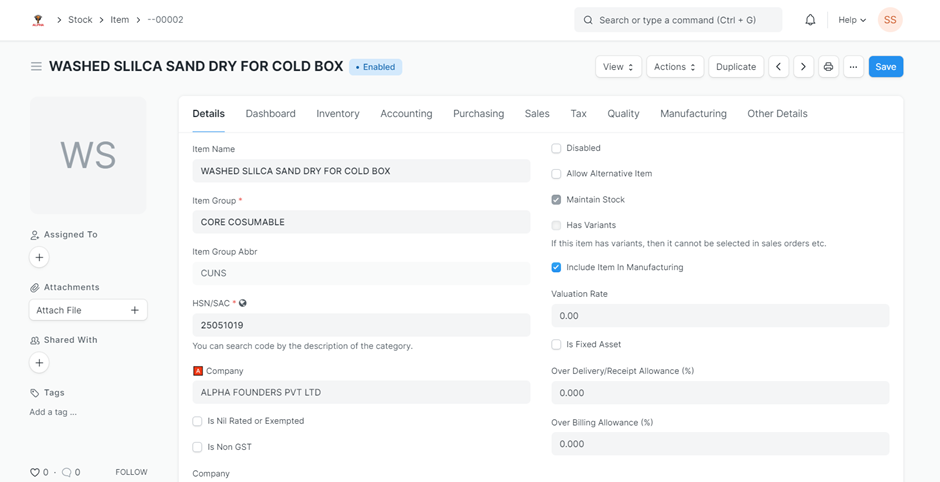

ITEM MASTER

Go to Item Master and click on "Add item"

o Series: Select the series as per the requirement

o Item Name: Item name is the actual name of your product or service. Enter an casting item name.

o Item Group: Item Group is used to categorize items. Enter the item group as per the item.

o Item Group Abbr : Item group abbr will be auto fetched from item group.

o HSN/SAC: Enter the item HSN code as per government rule.

o Default UOM: This is the default measuring unit that you will use for your item. Enter the UOM of item. It will be NOS, KG, etc.

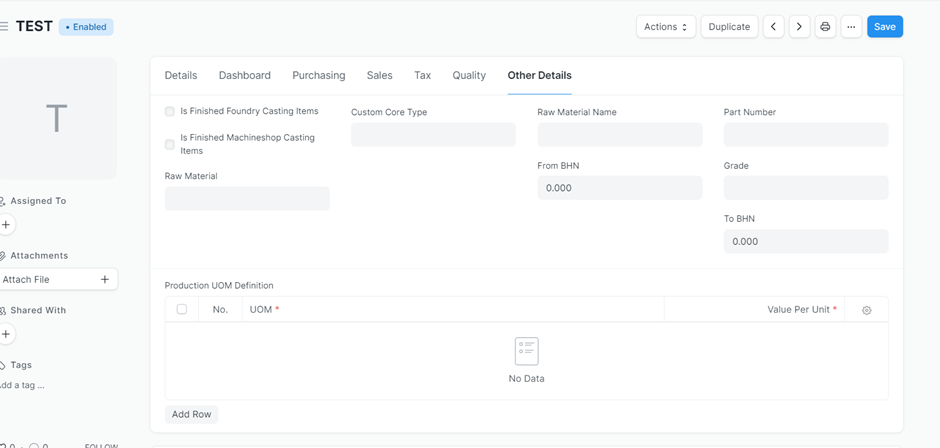

o Is Finished Foundry Casting Items: It used to separate the items for Machine shop and Foundry. If entered item is for Foundry then select "Is Finished Foundry Casting Items"

o Is Finished Machine shop Casting Items: If entered item is for machine shop then select "Is Finished Machine shop Casting Items"

*Note: Select any one from above as per the item group. This is already defined on item group. The check mark will auto fetched from system as per the item group data.

o Raw Material Item: If entered item is for machine shop then this field will be shown otherwise if entered item is for foundry this field will be hidden. Enter the raw material which will be used for casting treatment.

o Grade: Add the grade for entered item. This will be used for further process.

o Product UOM Definition: Add the UOM of item. It must be "Kg". Add value per unit.

o Click on Save

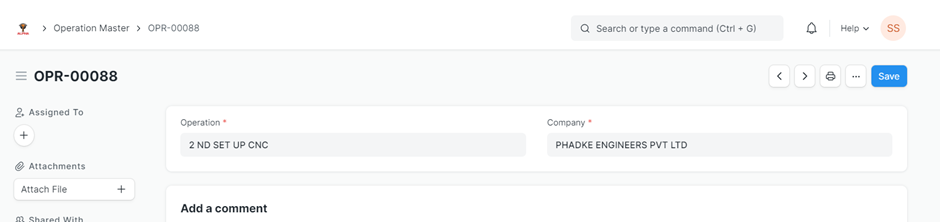

OPERATION MASTER

Go to Operation Master and Click on Add

o Write Name of Operation

o Select Company

o Click on Save

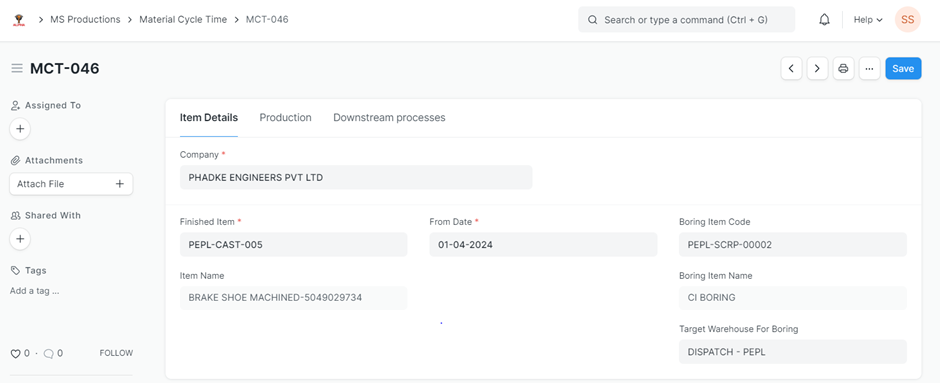

MACHINE CYCLE TIME

Prerequisites

o Item Master

o Warehouse

o Operation

o Machine Master

Go to Machine Cycle Time and Click on Add

o Select Company

o Select Finished Item From Item Master

o Select From Date to start cycle from

o Select Boring Item Code From Item Master where item is boring item

o Select target Warehouse

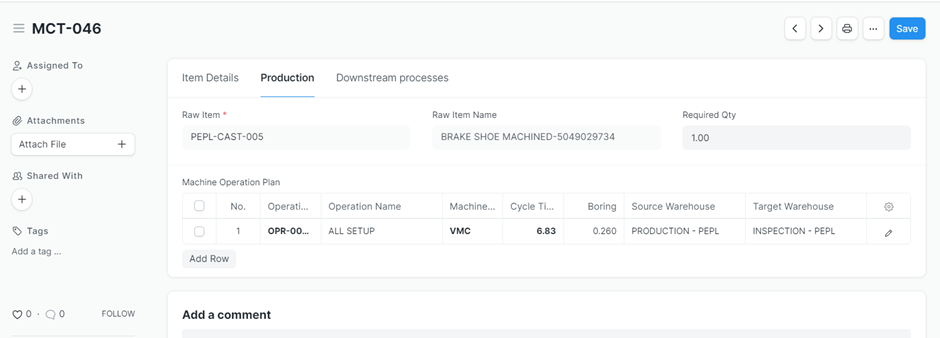

Go to Production Tab

o Select Operation

o Select Machine

o Write Cycle Time required for Machine to execute one cycle

o Write boring time required

o Select Source Warehouse and Target Warehouse

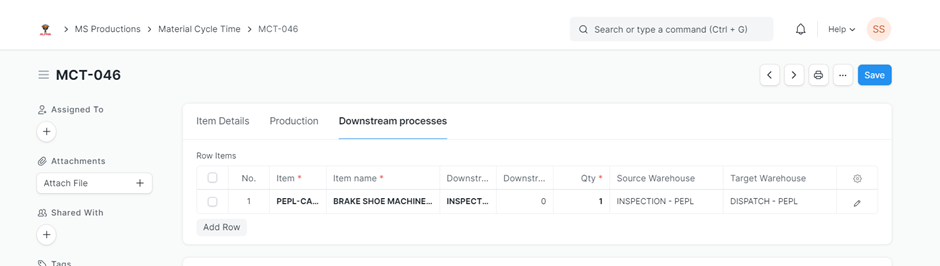

Go to Downstream Process Tab

o Select Downstream process

o Write Qty

o Select Source Warehouse and Target Warehouse

o Click On Save

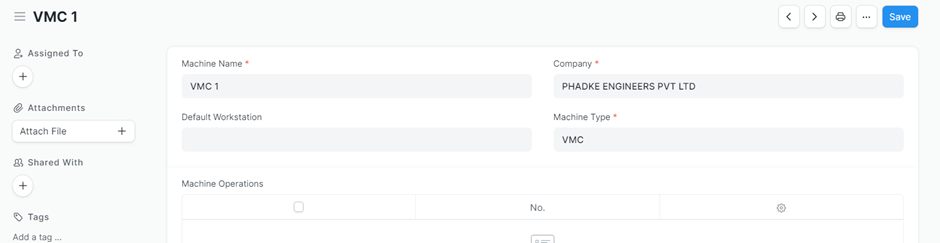

MACHINE MASTER

Go to Machine Master and Click on ADD

o Write Name of Machine

o Select Company

o Write Machine Type

o Click on Save

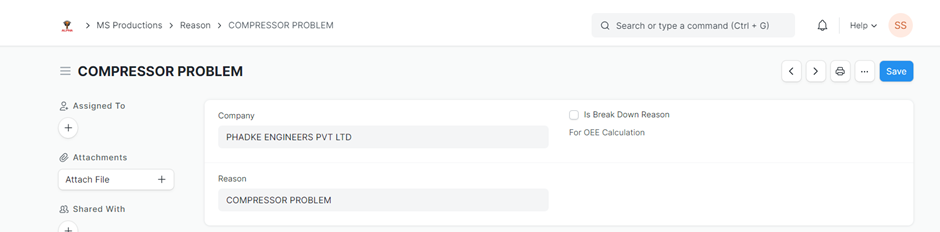

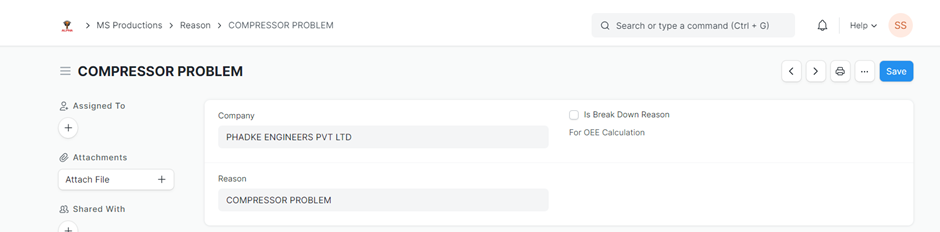

DOWNTIME REASON

Go to Downtime Reason and Click on ADD

o Writer down Reason

o Select Company

o Click on check box if this reason is used for OEE calculation

o Click on Save

REJECTION REASONS

These are reasons used when item is rejected

Go to Rejection Reason and Click on ADD

o Select Company

o Write Reason

o Click on Save