Manufacturing Work Order

It's like the formal instruction that puts your Manufacturing BOM into action. If the BOM is your cookbook, the Work Order is your decision to make a certain number of meals for tonight's dinner service. Both are essential for running an efficient, profitable manufacturing operation.

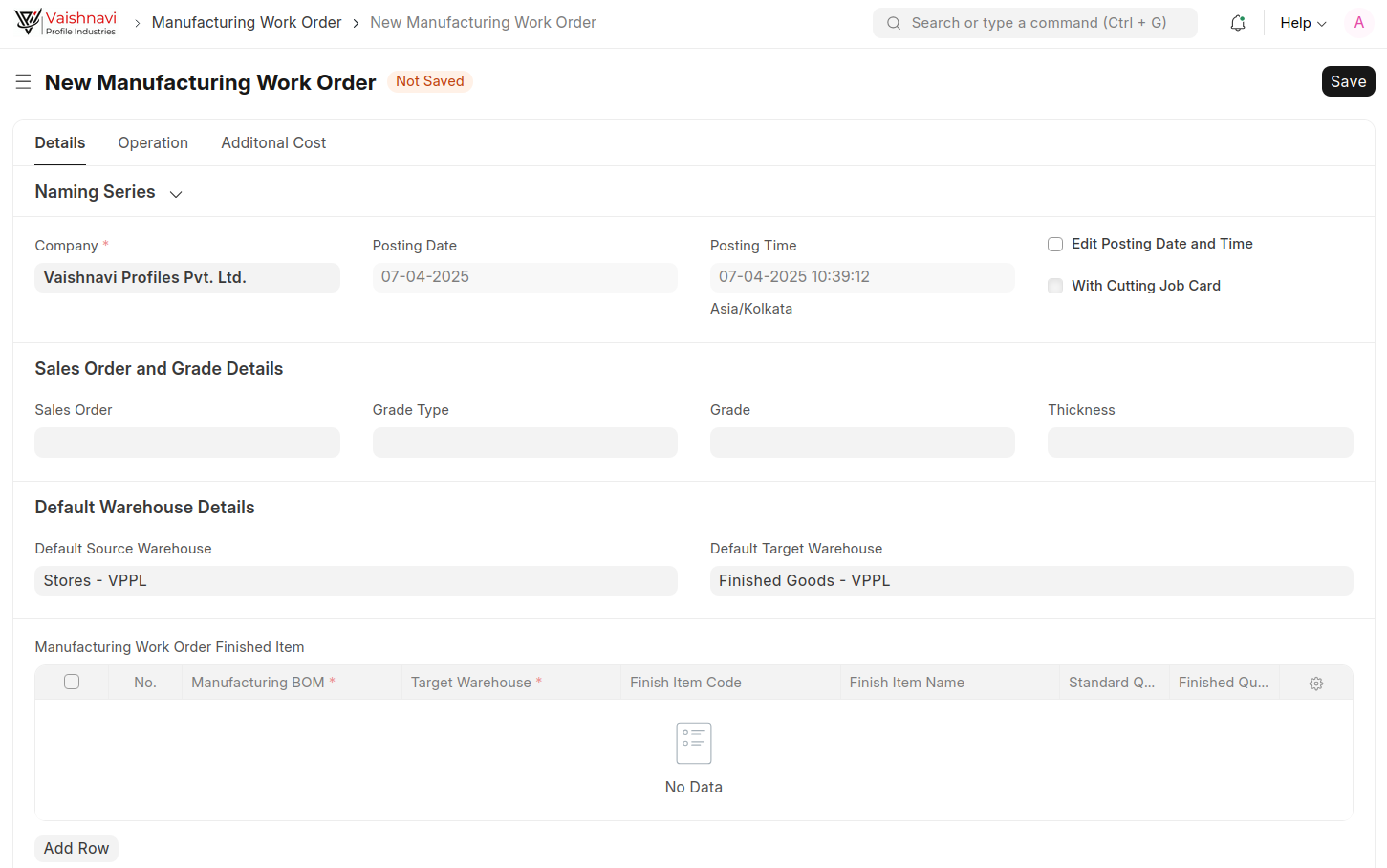

Step-by-step guide for creating a new Manufacturing Work Order

Step 1: Fill Sales Order and Grade Details

Enter the Sales Order number (e.g., SAL-ORD-2025-00007)

Select the Grade Type (e.g., steel)

Specify the Grade (e.g. A36, A572)

Enter Thickness if applicable

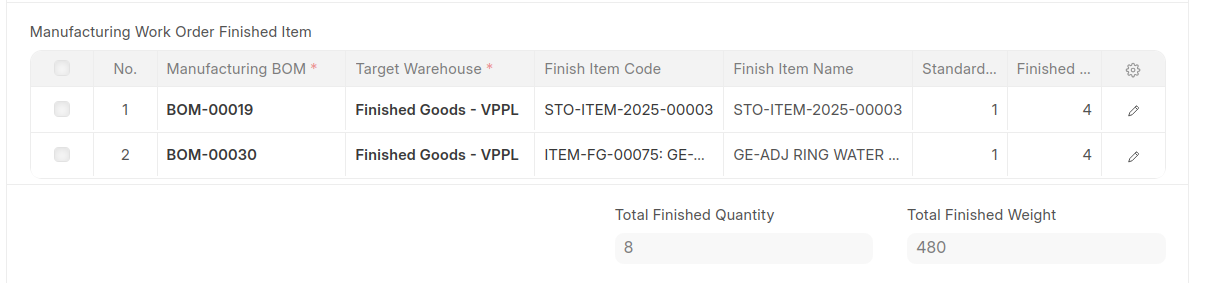

Step 2: Select Finished Item Details

Select the Manufacturing BOM (e.g., BOM-00019)

Verify the Target Warehouse

Review the Finish Item Code and Name that appear automatically

Enter the required Finished Quantity to fulfill the sales order

Important System Restrictions:

Total finished weight must be greater than the combined weight of all raw materials, usable scrap, scrap, and consumables.

The system prevents selecting the same manufacturing BOM multiple times in the Manufacturing Work Order Finished Item section to avoid duplication .

Fetches all required materials from the Manufacturing BOM :

Raw Materials with required quantities, Usable Scrap Materials , Consumable Materials , Scrap Materials

Populates required operations to manufacture the finished goods:

Operation sequence (e.g., Drilling, Cutting, Welding)

Required equipment and processes

Planned timing and costs

Step 3: Create job cards serve as work instructions

Once you've completed and submitted your Manufacturing Work Order (MWO-00110), two important custom buttons become available at the top of the screen:

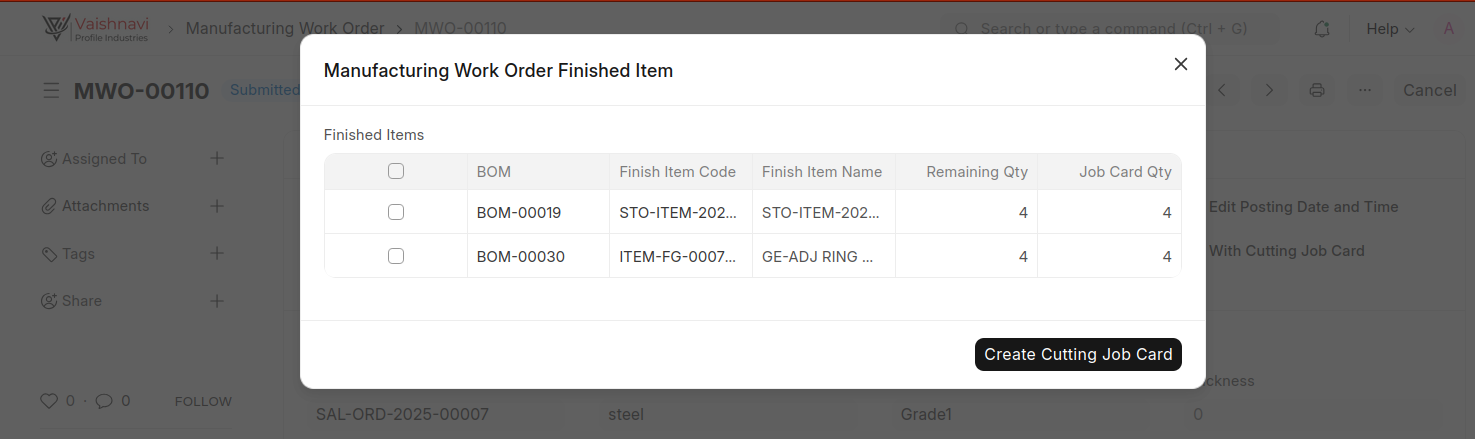

Create Cutting Job Card

Create Manufacturing Job Card

Creating Cutting Job Cards:

A dialog box will appear showing, ( Finish Item Names And codes, BOM numbers, Remaining Quantities and Job Card Quantities )

Select the items and quantity, The system will generate job cards specifically for cutting operations

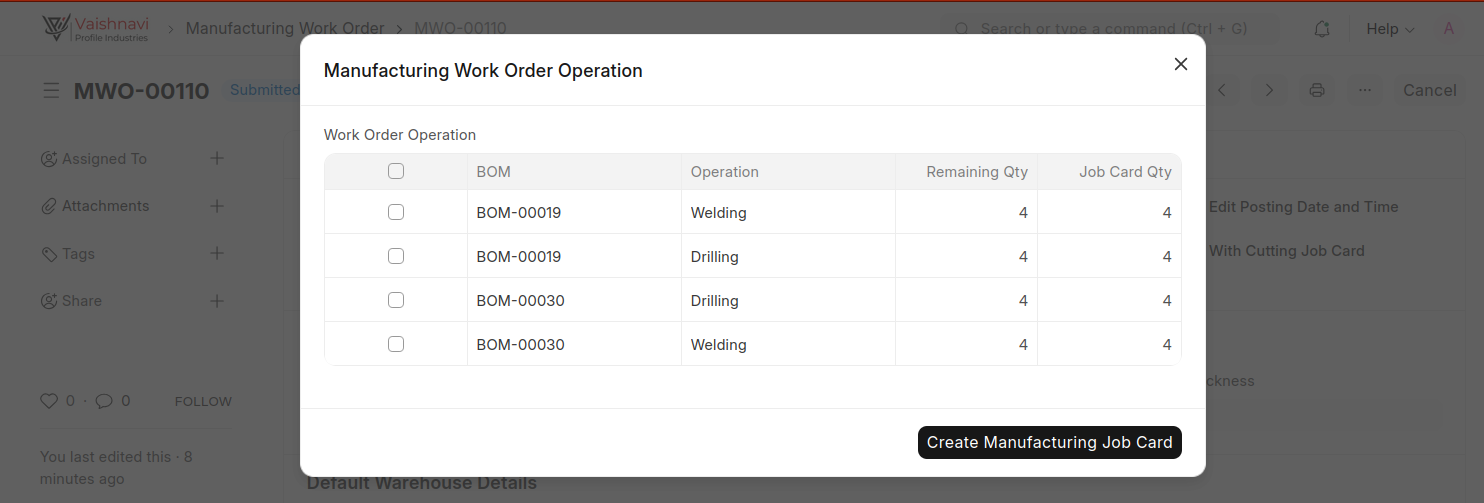

Creating Manufacturing Job Cards:

A dialog box will appear showing, ( BOM numbers, Operations [Welding, Drilling...etc], Remaining Quantities and Job Card Quantities )

Select the operations for which you want to create job cards,The system will generate job cards for each selected manufacturing operation.