DownStream Processes

DownStream Process

This process gives you details about downstream processes undergone for finished items.

Downstream processes are filled in downstream master file .

Steps and Fields Explanations :

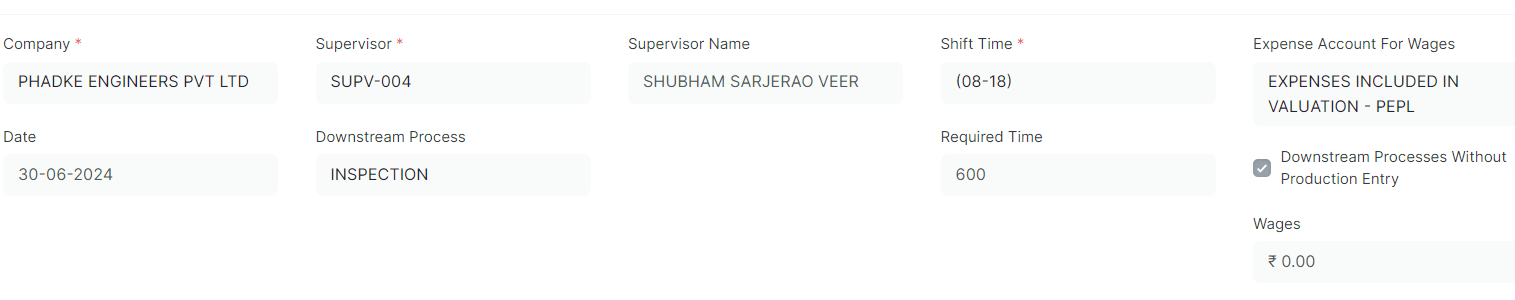

Select Company : Name of company for production item

Select Supervisor ID : Supervisor responsible for ITEM Supervisor Name will be

Auto populated

Select Shift Time : Shift time in which this production will be taking place (From Shift Master )

Required Time : This will be auto fetched from Shift Master depending on shift selected in minutes.

Select downstream process from downstream master

Checkbox Downstream processes without production entry is checked when downstream process we are doing is irrespective

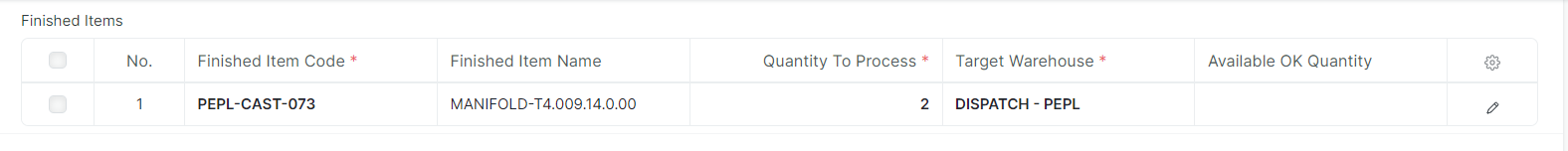

FINISHED ITEMS CHILD TABLE

Select Finished Item Code : This is Item we want to get finished as final product

Quantity to process process

Name and Warehouse will be auto filled from item master respective to code selected

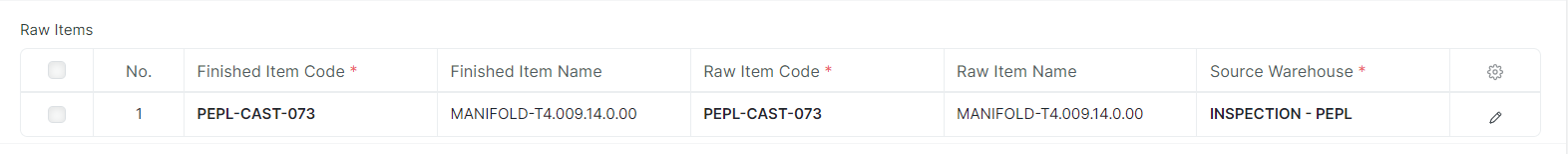

RAW ITEMS CHILD TABLE

This table will be auto filled depending on Finished Item Code with respect to data filled in ITEM MASTER

If clicked on edit row, We get details of available quantity of raw material from stock and also required time for raw item

If clicked on edit row, We get details of available quantity of raw material from stock and also required time for raw item

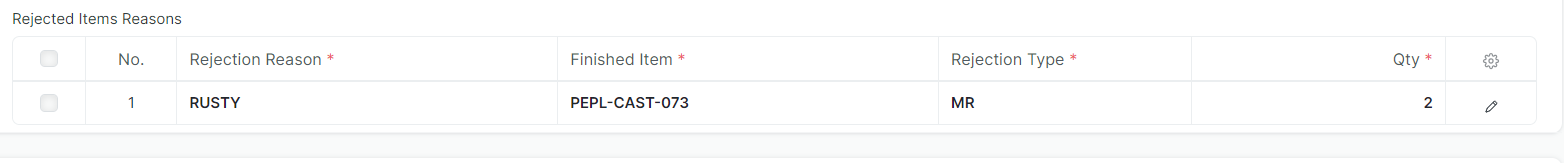

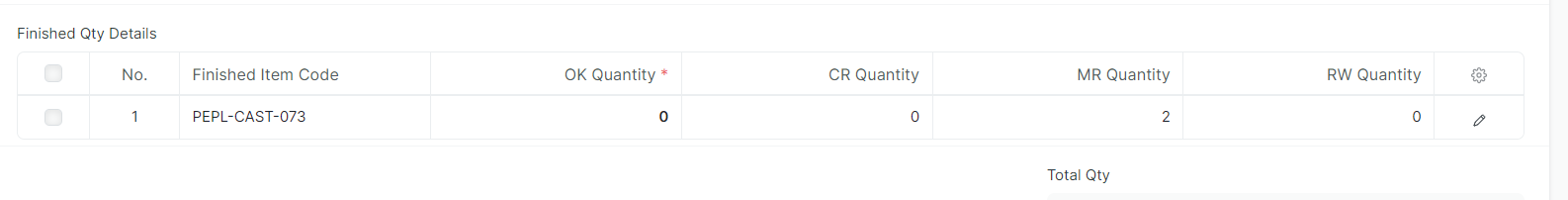

FINISHED ITEM QTY DETAILS

This table gives you information about OK quantity and rejected quantity as per type of rejection of items.

Need to enter OK quantity , CR,MR,RR quantity by user

clicking on button get rejected item, we get rejected items in rejected reason table and need to mention reason for every rejected item